Мегтрон 8 Субстрат Изготовитель

Мегтрон 8 Производитель подложек,Мегтрон 8 substrate is an advanced high-frequency laminate designed for demanding electronic applications. It offers exceptional thermal stability and low dielectric constant, making it ideal for RF and microwave circuits. Мегтрон 8 features low loss tangent properties, which help minimize signal degradation, ensuring high-performance signal integrity. The substrate is engineered for low moisture absorption and excellent dimensional stability, contributing to reliable operation in harsh environments. Its compatibility with fine-line processing makes it suitable for high-density interconnect designs, commonly used in telecommunications, автомобильный, and aerospace sectors. Полный, Мегтрон 8 is a preferred choice for engineers seeking superior performance in complex electronic systems.

What is Megtron 8 Субстрат?

Мегтрон 8 is a high-performance PCB substrate primarily used for high-speed and high-frequency electronic applications. This material was developed by the Japanese company Megtron and possesses excellent electrical and mechanical properties, meeting the increasingly stringent requirements of modern electronic products.

Мегтрон 8 substrates are made from a special resin material with a low dielectric constant and low loss factor, which ensures outstanding performance in high-frequency signal transmission. Compared to traditional FR-4 materials, Мегтрон 8 has better thermal stability and a lower coefficient of thermal expansion, effectively reducing structural deformation caused by temperature fluctuations. This characteristic is crucial for high-frequency circuit design, as even minor changes can significantly impact signal integrity during high-speed operations.

Дополнительно, Мегтрон 8 exhibits superior chemical resistance and moisture absorption rates, maintaining stable performance even in harsh environments. This substrate is widely used in communication devices, computer hardware, industrial automation, and automotive electronics.

Резюме, Мегтрон 8 has become an ideal choice for high-frequency and high-speed PCB design due to its exceptional electrical properties and superior mechanical performance, adapting to the rapid advancements in modern electronic technology.

Мегтрон 8 Производитель подложек

What is the Megtron 8 Substrate Design Guidelines?

The design guidelines for Мегтрон 8 Субстратов focus on optimizing performance in high-frequency and high-speed applications. Here are some key considerations:

- Layer Stackup: Ensure proper layer arrangement to minimize signal loss and maintain impedance control. Use microstrip or stripline configurations as needed.

- Ширина и интервал между трассами: Calculate trace widths carefully to maintain desired impedance levels. Pay attention to spacing between traces to avoid crosstalk.

- Проектирование переходных отверстий: Use blind and buried vias where possible to reduce inductance and improve signal integrity. Keep via diameters small to minimize parasitic capacitance.

- Ground Plane: Utilize continuous ground planes to reduce electromagnetic interference (EMI) and improve return paths for high-speed signals.

- Управление температурным режимом: Consider thermal dissipation, особенно в системах с высокой мощностью. Use thermal vias and pads strategically to enhance heat dissipation.

- Simulation Tools: Employ high-frequency simulation tools (like HFSS or ADS) during the design phase to validate signal integrity and electromagnetic performance.

- Manufacturing Tolerances: Be aware of the manufacturing capabilities and tolerances of the substrate. Collaborate with manufacturers early in the design process to ensure feasibility.

- Тестирование и валидация: Plan for appropriate testing methods, including TDR (Time Domain Reflectometry) and S-parameter measurements, to validate design performance post-manufacturing.

By adhering to these guidelines, designers can leverage the full capabilities of Megtron 8 substrates for reliable high-frequency and high-speed circuit performance.

The advantages of Megtron 8 Субстрат

Мегтрон 8 Субстратов offer several advantages, particularly suited for high-frequency and high-speed applications:

- Низкая диэлектрическая проницаемость: This property ensures minimal signal loss, enhancing signal integrity in high-speed circuits.

- Low Loss Factor: The substrate minimizes energy loss during signal transmission, which is crucial for maintaining performance in high-frequency applications.

- High Thermal Stability: Мегтрон 8 can withstand higher temperatures, reducing the risk of deformation and maintaining performance in demanding environments.

- Low Coefficient of Thermal Expansion: This helps in maintaining dimensional stability, reducing warping and stress during thermal cycling.

- Excellent Moisture Resistance: The substrate’s low moisture absorption rates prevent degradation in performance, particularly in humid conditions.

- Superior Chemical Resistance: It can withstand various chemicals, making it suitable for applications in harsh environments.

- Robust Mechanical Properties: Мегтрон 8 provides good mechanical strength, which aids in durability during handling and assembly.

- Многосторонность: It is suitable for a wide range of applications, including telecommunications, computing, автомобильный, and industrial electronics.

These advantages make Megtron 8 a preferred choice for engineers designing high-performance electronic systems.

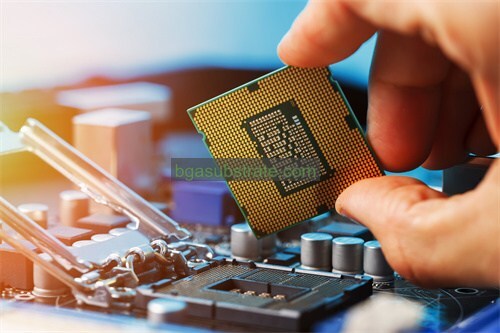

What is the Megtron 8 Substrate Fabrication Process?

The fabrication process for Megtron 8 substrates involves several key steps, ensuring high precision and quality suitable for high-frequency applications:

- Подготовка материала: Begin with the raw Megtron 8 material, which is a type of epoxy resin with specialized fillers. This material is available in sheets of varying thicknesses.

- Layer Cutting: Cut the Megtron 8 sheets to the required dimensions based on the design specifications.

- Copper Lamination: Bond copper foil to the surface of the substrate using heat and pressure. This is typically done in a lamination press to ensure a strong adhesion.

- Photo-Plotting: Apply a photoresist layer to the copper surface, followed by exposure to ultraviolet light through a photomask. This process defines the circuit patterns.

- Развивающийся: After exposure, the photoresist is developed, removing the unexposed areas and leaving the desired circuit pattern on the copper layer.

- Офорт: The exposed copper is chemically etched away, leaving the circuit traces intact on the substrate.

- Сверление: Holes for vias and component leads are drilled using precision drilling equipment. This step must be carefully controlled to maintain integrity.

- Переходное покрытие: If necessary, vias are plated with copper to create electrical connections between layers. This step may involve electroplating or chemical plating processes.

- Final Finishing: Additional processes, such as surface treatments or applying solder masks, may be applied to enhance performance and durability.

- Тестирование:Conduct rigorous testing to ensure electrical integrity and adherence to design specifications, including tests for impedance, Целостность сигнала, and thermal properties.

Выполнив следующие этапы изготовления, manufacturers can produce high-quality Megtron 8 substrates that meet the demanding requirements of modern electronic applications.

The application of ceramic Megtron 8 Субстрат

Ceramic Megtron 8 substrates are used in various applications due to their superior electrical and mechanical properties. Вот некоторые ключевые области применения:

- Электросвязь: Used in high-speed communication devices, such as routers and switches, where signal integrity is critical.

- Электроника: Found in smartphones, Таблетки, и игровые консоли, where compact design and high performance are required.

- Автомобильная электроника: Used in advanced driver-assistance systems (АДАС) and electric vehicle components, providing reliability in harsh environments.

- Industrial Automation: Employed in control systems and sensors, offering durability and performance in industrial settings.

- Аэрокосмическая и оборонная промышленность: Utilized in avionics and military communications, where high reliability and performance under extreme conditions are essential.

- Медицинские приборы: Implemented in diagnostic and monitoring equipment, ensuring precision and reliability in critical applications.

These applications leverage the thermal stability, low loss, and mechanical strength of Megtron 8 Субстратов, making them ideal for demanding electronic environments.

FAQs about Megtron 8 Субстрат

What is Megtron 8?

Мегтрон 8 is a high-performance PCB substrate designed for high-frequency and high-speed electronic applications, offering low dielectric constant and loss.

What are the main advantages of Megtron 8?

Key advantages include low signal loss, high thermal stability, low moisture absorption, and superior mechanical properties, making it ideal for demanding environments.

In which applications is Megtron 8 commonly used?

It is used in telecommunications, Электроника, automotive systems, industrial automation, аэрокосмический, оборона, and medical devices.

How does Megtron 8 compare to traditional FR-4 substrates?

Мегтрон 8 offers better performance at high frequencies, lower loss, improved thermal stability, and greater reliability in harsh conditions compared to FR-4.

What is the fabrication process for Megtron 8 Субстратов?

Процесс изготовления включает в себя подготовку материала, copper lamination, photo-plotting, офорт, сверление, via plating, and final finishing.

Can Megtron 8 substrates be used in multilayer designs?

Да, Мегтрон 8 substrates are suitable for multilayer designs, offering excellent performance and reliability across multiple layers.

What testing methods are used for Megtron 8 Субстратов?

Common testing methods include Time Domain Reflectometry (TDR), S-parameter measurements, and thermal cycling tests to ensure performance and reliability.

Are there specific design guidelines for Megtron 8?

Да, design guidelines include considerations for layer stackup, trace width and spacing, via design, ground plane usage, and thermal management.

Название вашего сайта

Название вашего сайта