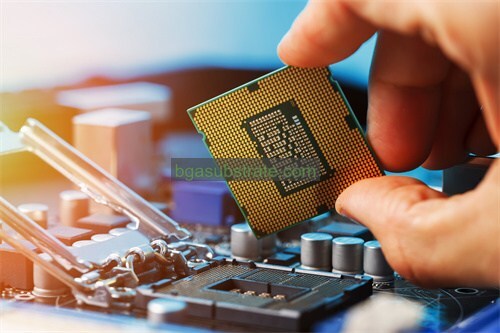

TU-900 Substrate Manufacturer

TU-900 Substrate Manufacturer,TU-900 substrate is an advanced laminate designed for high-frequency and high-speed applications in the electronics industry. It boasts a low dielectric constant and low loss tangent, ensuring optimal signal integrity for RF and microwave circuits. The substrate offers excellent thermal stability and low moisture absorption, making it reliable in demanding conditions. TU-900 is compatible with fine-line processing, allowing for complex multilayer designs and high-density interconnects. Widely used in telecommunications, aerospace, and automotive applications, TU-900 meets the rigorous performance standards required for modern electronic devices, providing engineers with a dependable solution for their high-performance needs.

What is TU-900 Substrate?

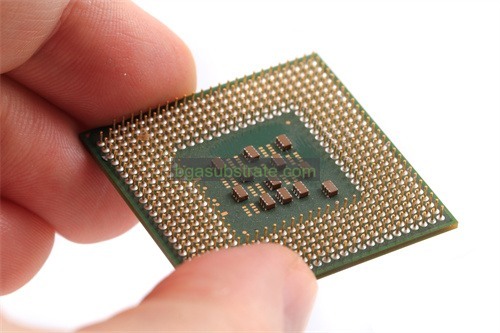

The TU-900 substrate is a high-performance ceramic substrate primarily used in high-frequency and high-power electronic devices. It has gained widespread attention for its excellent electrical properties and thermal stability, particularly in radio frequency (RF) and microwave applications.

Key characteristics of the TU-900 substrate include a low dielectric constant and low dielectric loss, making it highly suitable for high-speed signal transmission circuits. Its superior thermal conductivity ensures effective heat dissipation under high-power operating conditions, thereby extending the lifespan of electronic components. Additionally, the TU-900 substrate possesses good mechanical strength, allowing it to maintain stable performance in harsh environments.

The TU-900 substrate is widely used in communications, automotive electronics, medical devices, and aerospace industries. In the communication sector, it is commonly utilized in critical components such as antennas, filters, and amplifiers. In automotive electronics, it can be found in sensors and control modules, ensuring reliability under high-temperature and high-pressure conditions.

In summary, the TU-900 substrate is becoming an important choice in high-end electronic products due to its outstanding performance and diverse application prospects. With ongoing technological advancements, the range of applications for the TU-900 substrate is expected to expand further, driving the development of the electronics industry.

TU-900 Substrate Manufacturer

What is the TU-900 Substrate Design Guidelines?

The design guidelines for the TU-900 substrate focus on optimizing its performance in high-frequency and high-power applications. Key considerations include:

- Layer Structure: Ensure the substrate’s layer configuration supports the intended application, such as RF circuits or microwave components.

- Trace Width and Spacing: Calculate appropriate trace widths and spacing to maintain impedance control and reduce signal loss. This is critical for high-speed signal integrity.

- Thermal Management: Incorporate thermal vias and adequate copper thickness to enhance heat dissipation, especially in high-power applications.

- Via Design: Utilize microvias or blind/buried vias to minimize inductance and maintain signal integrity. Consider the aspect ratio to ensure manufacturability.

- Surface Finish: Select an appropriate surface finish to improve solderability and reduce oxidation, enhancing reliability.

- Ground Plane: Implement a continuous ground plane to reduce electromagnetic interference (EMI) and improve overall performance.

- Mechanical Considerations: Account for mechanical stresses, especially in applications with thermal cycling, to prevent cracking or delamination.

- Electrical Isolation: Ensure sufficient isolation between high-frequency traces and sensitive components to minimize interference.

- Testing and Prototyping: Conduct thorough testing of prototypes to validate performance against design expectations, especially for critical parameters like dielectric constant and loss.

Following these guidelines helps maximize the performance and reliability of designs using the TU-900 substrate in demanding applications.

The advantages of TU-900 Substrate

The TU-900 substrate offers several advantages, making it a preferred choice for various high-frequency and high-power applications:

- Low Dielectric Loss: Its low dielectric loss allows for minimal signal attenuation, ensuring efficient signal transmission in RF and microwave circuits.

- High Thermal Conductivity: The substrate provides excellent thermal management, enabling effective heat dissipation and enhancing the reliability of high-power devices.

- Stable Electrical Performance: With a low dielectric constant, the TU-900 substrate maintains stable electrical properties across a wide frequency range, making it suitable for high-speed applications.

- Mechanical Strength: Its robust mechanical properties allow it to withstand harsh environments, reducing the risk of cracking or delamination.

- Compatibility with Advanced Manufacturing: The TU-900 substrate is compatible with various PCB manufacturing processes, enabling the integration of complex circuit designs.

- Excellent EMI Shielding: The substrate’s construction provides effective electromagnetic interference shielding, improving overall circuit performance.

- Versatility: Suitable for a wide range of applications, including telecommunications, automotive electronics, and aerospace, the TU-900 substrate adapts well to diverse industry needs.

- Enhanced Reliability: Its durable nature and stable performance contribute to the long-term reliability of electronic devices, especially in demanding conditions.

These advantages make the TU-900 substrate an excellent choice for designers looking to enhance the performance and reliability of their electronic products.

What is the TU-900 Substrate Fabrication Process?

The TU-900 substrate fabrication process is associated with a specific type of high-performance substrate used in advanced electronic applications, such as RF and microwave circuits. The TU-900 process involves several key steps:

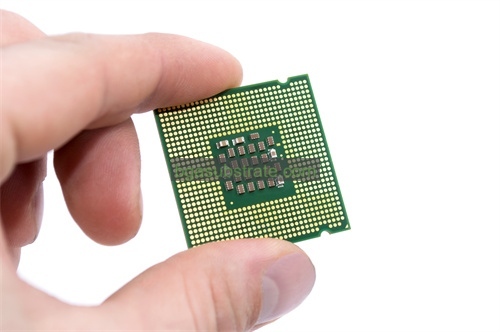

- Material Preparation: This involves selecting and preparing the base material, which is usually a type of ceramic or composite material that provides the desired electrical and thermal properties.

- Deposition: Thin films of conductive materials, like copper, are deposited onto the substrate. This can be done using techniques like sputtering or electroplating.

- Patterning: Photolithography or other patterning techniques are used to define the circuit layout on the substrate. This process involves coating the substrate with a light-sensitive material, exposing it to a pattern of light, and then etching away the unexposed material to create the desired circuit patterns.

- Etching: The exposed areas of the substrate are etched away to remove excess material, leaving behind the defined circuit patterns.

- Lamination: For multi-layer substrates, layers of material are laminated together using heat and pressure. This step is crucial for creating complex, multi-layer circuits.

- Testing and Quality Control: The fabricated substrates undergo rigorous testing to ensure they meet performance and quality standards.

The TU-900 process is designed to produce substrates with high precision and reliability, often used in demanding applications where performance and durability are critical.

The application of ceramic TU-900 Substrate

Ceramic TU-900 substrates are used in various high-performance electronic applications due to their excellent electrical, thermal, and mechanical properties. Here are some key applications:

- RF and Microwave Circuits: TU-900 substrates are ideal for high-frequency applications due to their low dielectric loss and stable electrical performance. They are commonly used in RF amplifiers, oscillators, and filters.

- Aerospace and Defense: In aerospace and defense industries, where reliability and performance under extreme conditions are critical, TU-900 substrates are used in radar systems, communication devices, and other advanced electronic systems.

- Automotive Electronics: These substrates are used in automotive electronics for high-frequency applications such as radar sensors and advanced driver-assistance systems (ADAS), where durability and high performance are essential.

- Telecommunications: In telecommunications, TU-900 substrates support high-speed data transmission and signal integrity, making them suitable for components like base stations and communication modules.

- Medical Devices: The high thermal conductivity and electrical performance of TU-900 substrates make them suitable for medical devices that require precise and reliable electronic performance.

- High-Power Electronics: Due to their excellent thermal management properties, TU-900 substrates are used in high-power electronic devices, including power amplifiers and high-power RF circuits.

Their ability to handle high frequencies and power levels, combined with their thermal and mechanical stability, makes ceramic TU-900 substrates a preferred choice for demanding electronic applications.

FAQs about TU-900 Substrate

What is a TU-900 substrate?

TU-900 is a type of ceramic substrate known for its high performance in RF and microwave applications. It provides excellent electrical and thermal properties.

What are the key features of TU-900 substrates?

Key features include low dielectric loss, high thermal conductivity, mechanical stability, and high-frequency performance.

What are TU-900 substrates used for?

They are used in RF and microwave circuits, aerospace and defense systems, automotive electronics, telecommunications, medical devices, and high-power electronics.

Why are TU-900 substrates preferred in high-frequency applications?

They offer low signal loss and stable electrical performance, which are crucial for maintaining signal integrity at high frequencies.

How do TU-900 substrates manage heat?

TU-900 substrates have high thermal conductivity, which helps dissipate heat effectively and prevent overheating in high-power applications.

Are TU-900 substrates suitable for all electronic applications?

While TU-900 substrates are excellent for high-frequency and high-power applications, they may not be necessary for lower-frequency or less demanding applications.

Your Website Name

Your Website Name