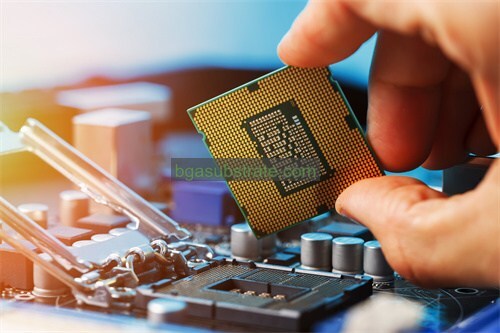

Mitsubishi BGA Substrate Manufacturer

Mitsubishi BGA Substrate Manufacturer,Mitsubishi BGA Substrate is a cutting-edge solution for high-density semiconductor packaging. Known for its advanced design and manufacturing, it offers excellent thermal management and electrical performance crucial for modern electronic devices. Mitsubishi BGA Substrate supports complex integrated circuits with high pin counts, ensuring reliable connectivity and signal integrity. Its materials provide low thermal expansion and exceptional mechanical strength, making it suitable for applications in telecommunications, computing, and automotive electronics. Engineers rely on Mitsubishi BGA Substrate for its precision, durability, and ability to meet stringent requirements of advanced packaging technologies, facilitating compact and efficient electronic systems.

What is Mitsubishi BGA Substrate?

Mitsubishi BGA Substrate refers to Ball Grid Array (BGA) substrates manufactured by Mitsubishi Electric Corporation. These substrates are crucial components in electronic packaging, facilitating the interconnection between integrated circuits (ICs) and PCBs. Mitsubishi’s BGA substrates are known for their high reliability, thermal performance, and electrical integrity, making them suitable for various applications requiring compact and efficient circuit integration.

These substrates typically feature advanced materials and precise manufacturing processes to ensure optimal performance in demanding environments. They are designed to support high-density interconnects, allowing for the integration of multiple ICs in a compact space while maintaining signal integrity and thermal management.

Mitsubishi’s expertise in BGA substrates extends to various forms, including those optimized for different thermal management needs, high-frequency applications, and specific mechanical requirements. Their products often adhere to industry standards and are tailored to meet the evolving needs of modern electronics, ensuring robust performance and reliability in electronic assemblies.

Mitsubishi BGA Substrate Manufacturer

What is the Mitsubishi BGA Substrate Design Guidelines?

The design guidelines for Mitsubishi BGA substrates provide detailed instructions and recommendations for engineers and designers to ensure the optimal performance, reliability, and manufacturability of their BGA-based electronic assemblies. These guidelines typically cover several key aspects:

- Pad and Via Design: Specifications for pad sizes, shapes, and pitches are detailed to ensure proper soldering and electrical connectivity. Guidelines for via sizes, placement, and anti-pad requirements are also included to minimize signal interference and ensure thermal management.

- Layer Stackup: Recommendations for the layer configuration and materials used in the substrate construction to achieve desired electrical properties, thermal performance, and mechanical stability. This includes considerations for signal integrity, power distribution, and grounding strategies.

- Thermal Management: Guidelines for thermal vias, thermal pad placement, and thermal conductivity requirements to manage heat dissipation effectively. This is critical for maintaining operational reliability and preventing thermal stress on components.

- Signal Integrity: Design recommendations to minimize impedance mismatch, crosstalk, and other signal integrity issues. This includes controlled impedance routing, spacing guidelines for signal traces, and isolation techniques for sensitive signals.

- Mechanical Considerations:Specifications for substrate dimensions, warpage control, and mechanical strength to ensure compatibility with assembly processes and mechanical reliability in use.

- Manufacturability:Guidelines to facilitate efficient manufacturing processes, such as panelization requirements, fiducial placement for alignment, and design for automated assembly and inspection.

- Environmental and Electrical Testing: Recommendations for environmental testing conditions and electrical testing methodologies to validate substrate performance under various operational conditions and ensure compliance with industry standards.

These guidelines are essential for designers to leverage Mitsubishi BGA substrates effectively, ensuring that their designs meet performance requirements while being manufacturable and reliable in real-world applications.

The advantages of Mitsubishi BGA Substrate

Mitsubishi BGA substrates offer several advantages that make them preferred choices in electronic packaging and interconnect solutions:

- High Reliability: Mitsubishi’s substrates are known for their robust construction and reliable performance, meeting stringent quality standards. This reliability is crucial for applications requiring long-term operation and durability.

- Excellent Thermal Management: These substrates are designed to efficiently dissipate heat generated by integrated circuits, enhancing thermal management capabilities. This helps in maintaining optimal operating temperatures and prolonging component lifespan.

- High Density Interconnects: Mitsubishi BGA substrates support high-density packaging, allowing for the integration of multiple components in a compact space. This density is essential for miniaturization and space-saving in modern electronic devices.

- Signal Integrity:They are engineered to minimize signal loss, crosstalk, and impedance mismatch, ensuring high signal integrity across the substrate. This is critical for maintaining data transmission quality and reliability in high-speed applications.

- Versatility: Mitsubishi offers a range of BGA substrates tailored to different application needs, including variations optimized for specific thermal, electrical, or mechanical requirements. This versatility allows designers to select substrates that best fit their project specifications.

- Advanced Materials and Technology: Leveraging Mitsubishi’s expertise in materials science and manufacturing technology, these substrates often incorporate advanced materials and precise manufacturing processes to achieve superior performance and reliability.

- Compliance and Standards: Mitsubishi BGA substrates adhere to industry standards and regulations, ensuring compatibility and reliability in diverse electronic assemblies. This compliance simplifies integration into existing designs and systems.

Overall, Mitsubishi BGA substrates combine advanced technology, reliability, and thermal management capabilities to meet the demanding requirements of modern electronic applications, making them a preferred choice for engineers and designers.

What is the Mitsubishi BGA Substrate Fabrication Process?

The fabrication process for Mitsubishi BGA (Ball Grid Array) substrates involves several key steps to ensure the production of high-quality substrates that meet stringent performance and reliability requirements:

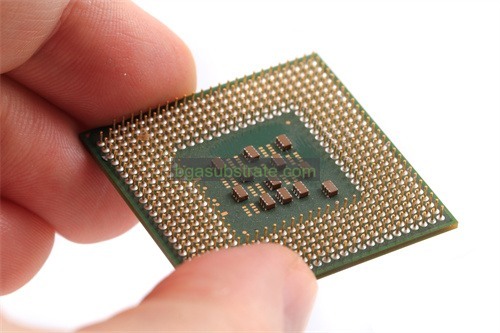

- Substrate Material Selection: Mitsubishi selects appropriate substrate materials based on the specific application requirements, such as thermal conductivity, electrical properties, and mechanical strength.

- Preparation of Substrate Layers: Multiple layers of the substrate material are prepared according to the design specifications. This includes cutting the substrate material into panels or sheets of appropriate sizes.

- Layer Alignment and Lamination: The individual substrate layers are aligned precisely according to the design stack-up and then laminated together under controlled temperature and pressure conditions. This process ensures a strong bond between layers.

- Drilling and Via Formation: After lamination, holes are drilled through the substrate stack where vias are required. Vias are conductive pathways that connect different layers of the substrate to facilitate electrical connections.

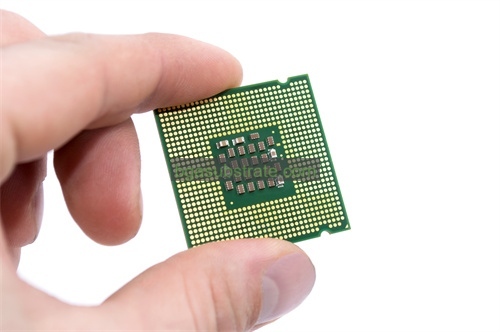

- Copper Deposition and Patterning: Copper is deposited onto the substrate surface through a process such as electroplating or sputtering. This copper layer is then patterned using photolithography and etching techniques to define the circuit traces and pads.

- Surface Finish: The exposed copper surfaces are typically coated with a surface finish to protect against oxidation and facilitate soldering during assembly. Common surface finishes include electroless nickel immersion gold (ENIG) or solder mask application.

- Solder Mask Application: A solder mask layer is applied over the substrate to define and protect the copper traces, leaving exposed only the areas where electrical connections (pads) will be made with components.

- Final Inspection and Testing: The completed BGA substrates undergo thorough inspection and testing to ensure dimensional accuracy, electrical continuity, signal integrity, and compliance with design specifications and industry standards.

- Packaging and Shipping: Once validated, the substrates are packaged securely to prevent damage during transport and storage until they are ready for assembly into electronic devices.

Throughout the fabrication process, Mitsubishi employs stringent quality control measures and advanced manufacturing techniques to produce BGA substrates that offer superior performance, reliability, and durability for a wide range of electronic applications.

The application of ceramic Mitsubishi BGA Substrate

Mitsubishi ceramic BGA (Ball Grid Array) substrates find application in various industries and electronic devices where high reliability, thermal management, and compact design are critical. Some key applications include:

- Semiconductor Devices: Mitsubishi BGA substrates are widely used in semiconductor packaging, providing a reliable platform for mounting and interconnecting integrated circuits (ICs). They support high-density interconnects and effective thermal dissipation, crucial for modern semiconductor devices.

- Consumer Electronics:In consumer electronics such as smartphones, tablets, and laptops, Mitsubishi BGA substrates are used to miniaturize and integrate complex electronic circuits. Their thermal management capabilities help in maintaining device performance and reliability.

- Automotive Electronics: BGA substrates are employed in automotive electronics for applications like engine control units (ECUs), infotainment systems, and advanced driver-assistance systems (ADAS). They withstand harsh environmental conditions and temperature fluctuations while ensuring long-term reliability.

- Telecommunications: In telecommunications equipment such as routers, switches, and base stations, Mitsubishi BGA substrates support high-speed data transmission and signal integrity. They enable compact designs that meet the demands of telecommunications infrastructure.

- Industrial Equipment: BGA substrates play a crucial role in industrial equipment where reliability and durability are paramount. They are used in control systems, power electronics, and industrial automation applications, ensuring stable operation under varying conditions.

- Medical Devices: Mitsubishi BGA substrates are utilized in medical devices where compact size, reliability, and performance are essential. They are employed in devices such as diagnostic equipment, patient monitoring systems, and medical imaging devices.

- Aerospace and Defense: In aerospace and defense applications, BGA substrates from Mitsubishi support critical electronic systems in aircraft, satellites, and military equipment. They offer robust performance in demanding environments and adhere to stringent quality and reliability standards.

In each of these applications, Mitsubishi BGA substrates contribute to enhancing device performance, reducing size and weight, improving thermal management, and ensuring the overall reliability and longevity of electronic systems. Their versatility and advanced features make them integral components in a wide range of high-tech industries.

FAQs about Mitsubishi BGA Substrate

What are Mitsubishi BGA substrates used for?

Mitsubishi BGA substrates are used in various electronic applications where compact size, high-density interconnects, and excellent thermal management are required. They are commonly used in semiconductor devices, consumer electronics, automotive electronics, telecommunications equipment, medical devices, and aerospace applications.

What are the advantages of Mitsubishi BGA substrates?

Mitsubishi BGA substrates offer advantages such as high reliability, excellent thermal dissipation, high-density packaging capabilities, superior signal integrity, and versatility in meeting specific application requirements. They are designed to enhance performance and reliability in electronic assemblies.

What materials are Mitsubishi BGA substrates made from?

Mitsubishi BGA substrates are typically made from ceramic materials such as alumina (Al2O3) or aluminum nitride (AlN). These materials provide good thermal conductivity, electrical insulation, and mechanical strength, making them suitable for demanding electronic applications.

What are the thermal management capabilities of Mitsubishi BGA substrates?

Mitsubishi BGA substrates are engineered to efficiently dissipate heat generated by integrated circuits (ICs). They incorporate features like thermal vias, thermal pads, and optimized layer stack-ups to manage thermal dissipation effectively, ensuring stable operation and prolonged component lifespan.

Are Mitsubishi BGA substrates compliant with industry standards?

Yes, Mitsubishi BGA substrates adhere to industry standards and regulations to ensure compatibility, reliability, and performance in electronic assemblies. They undergo rigorous testing and quality control processes to meet the requirements of various industries and applications.

What customization options are available for Mitsubishi BGA substrates?

Mitsubishi offers customization options for BGA substrates to meet specific customer requirements. This includes variations in material composition, layer stack-up configurations, surface finishes, and design features tailored to optimize performance in different applications.

How can Mitsubishi BGA substrates contribute to reducing the size of electronic devices?

By supporting high-density interconnects and compact designs, Mitsubishi BGA substrates enable the miniaturization of electronic devices. This reduction in size is crucial for applications where space-saving and lightweight designs are desired without compromising performance or reliability.

Your Website Name

Your Website Name