ISOLAI I SPEED Substrate Manufacturer

ISOLAI I SPEED Substrate Manufacturer,ISOLA I SPEED is a high-performance substrate engineered for advanced electronic applications requiring exceptional speed and reliability. It boasts superior electrical properties, including low dielectric loss and a stable dielectric constant, which enhance signal integrity and minimize signal degradation. The substrate also offers excellent thermal management capabilities, ensuring efficient heat dissipation and contributing to the overall reliability and longevity of electronic devices. ISOLA I SPEED is designed to meet the rigorous demands of high-frequency and high-speed circuit designs, making it an ideal choice for cutting-edge applications in the electronics industry.

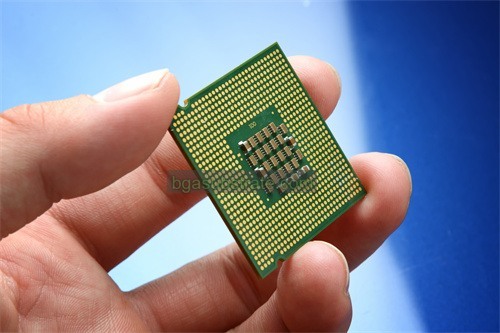

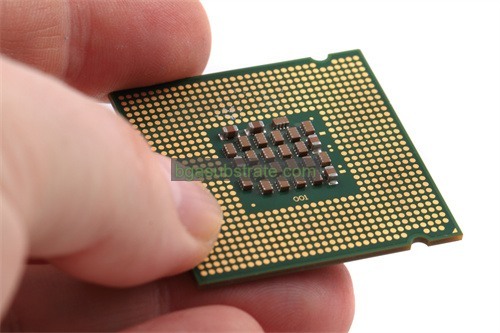

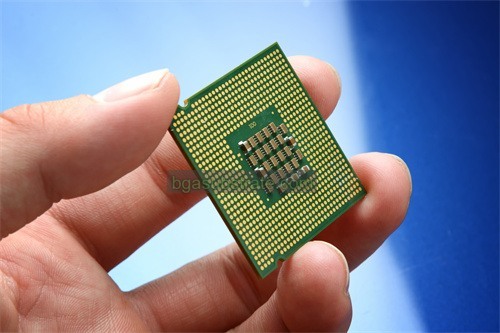

What is ISOLAI I SPEED Substrate?

ISOLAI I SPEED substrate is an advanced material designed for high-performance electronic applications, particularly in the realm of semiconductor packaging and advanced PCB (Printed Circuit Board) technologies. This substrate is notable for its combination of high thermal conductivity and low dielectric loss, making it an ideal choice for demanding applications that require efficient heat dissipation and signal integrity.

The ISOLAI I SPEED substrate incorporates advanced materials and manufacturing techniques to achieve superior performance. It typically features a core layer made from high-quality ceramic or composite materials that provide excellent thermal and electrical insulation. This is often combined with metal layers, such as copper, to enhance electrical conductivity and support complex circuit designs. The substrate’s construction is designed to manage the thermal and mechanical stresses encountered in high-speed and high-power applications, ensuring reliability and longevity.

In terms of performance, ISOLAI I SPEED substrates are engineered to support high-speed signal transmission with minimal attenuation and distortion. This is crucial for applications in telecommunications, high-frequency RF circuits, and other areas where signal integrity is paramount. Additionally, the substrate’s thermal management capabilities help prevent overheating and maintain consistent performance under varying operational conditions.

Overall, ISOLAI I SPEED substrates are tailored for advanced electronic systems where both electrical performance and thermal management are critical. Their high-quality construction and material properties make them suitable for cutting-edge technologies and high-performance applications, providing a reliable solution for modern electronic and semiconductor needs.

ISOLAI I SPEED Substrate Manufacturer

What is the ISOLAI I SPEED Substrate Design Guidelines?

The ISOLAI I SPEED substrate design guidelines provide essential recommendations for optimizing the performance and reliability of electronic systems using this advanced substrate material. These guidelines are critical for ensuring that the substrate’s thermal, electrical, and mechanical properties are fully leveraged in high-performance applications.

- Thermal Management:Effective thermal management is crucial when designing with ISOLAI I SPEED substrates. Designers should ensure that heat dissipation paths are well-defined and that thermal vias and heat sinks are appropriately placed to avoid hotspots. The substrate’s high thermal conductivity helps in spreading heat efficiently, but careful design is needed to ensure uniform temperature distribution and prevent thermal stress.

- Signal Integrity:To maintain high signal integrity, minimize signal attenuation and distortion by following precise trace layout guidelines. Keep high-speed signal traces short and direct, and use controlled impedance techniques to match the substrate’s characteristics. Proper grounding and shielding techniques should be employed to reduce electromagnetic interference (EMI) and crosstalk between traces.

- Mechanical Stability: Ensure that the substrate design accounts for mechanical stress and strain. Utilize appropriate mounting and support structures to prevent mechanical failure or warping. Pay special attention to the substrate’s mechanical bonding with other components, and design for adequate support during assembly and operation.

- Layer Stack-Up: Design the layer stack-up carefully to balance electrical performance and thermal management. The ISOLAI I SPEED substrate’s composite layers should be configured to optimize signal routing and heat dissipation. Maintain proper spacing between layers to prevent signal coupling and interference.

- Manufacturing Tolerances:Adhere to the manufacturer’s specifications for material thickness, trace width, and other critical dimensions. Accurate fabrication and assembly processes are essential to achieving the substrate’s intended performance characteristics and ensuring consistency across production runs.

By following these design guidelines, engineers can fully exploit the benefits of ISOLAI I SPEED substrates, ensuring that they deliver optimal performance in high-speed, high-power electronic applications while maintaining reliability and durability.

The advantages of ISOLAI I SPEED Substrate

The ISOLAI I SPEED substrate offers several key advantages, making it a preferred choice for high-performance electronic applications. These advantages stem from its advanced material properties and design features, which cater to the demands of modern semiconductor and PCB technologies.

- High Thermal Conductivity:ISOLAI I SPEED substrates are engineered with materials that provide excellent thermal conductivity. This allows for effective heat dissipation, reducing the risk of overheating and ensuring stable operation even in high-power applications. The substrate’s ability to manage thermal stress enhances the reliability and longevity of the electronic components.

- Low Dielectric Loss:The substrate features low dielectric loss characteristics, which contribute to high signal integrity. This is crucial for high-speed and high-frequency applications where signal attenuation and distortion must be minimized. The low dielectric loss ensures that signals remain clear and accurate, enhancing overall performance.

- Enhanced Electrical Performance:ISOLAI I SPEED substrates are designed to support high-speed signal transmission with minimal interference. The substrate’s material properties enable controlled impedance, reducing crosstalk and electromagnetic interference (EMI) between traces. This results in improved signal clarity and overall system performance.

- Mechanical Stability:The substrate provides robust mechanical stability, which is essential for maintaining structural integrity during operation. It is designed to handle mechanical stresses and prevent warping or deformation, ensuring reliable performance under varying conditions.

- Versatility:ISOLAI I SPEED substrates are versatile and can be used in a wide range of applications, from telecommunications to high-frequency RF circuits. Their ability to accommodate complex designs and diverse operational requirements makes them suitable for advanced electronic systems.

- Durability:The high-quality materials used in ISOLAI I SPEED substrates contribute to their durability and resistance to environmental factors such as moisture and temperature fluctuations. This ensures long-term reliability and consistent performance.

Overall, the ISOLAI I SPEED substrate offers a combination of high thermal conductivity, low dielectric loss, enhanced electrical performance, mechanical stability, versatility, and durability. These advantages make it a valuable choice for cutting-edge electronic and semiconductor applications that require superior performance and reliability.

What is the ISOLAI I SPEED Substrate Fabrication Process?

The ISOLAI I SPEED substrate fabrication process involves several critical steps to ensure the production of high-quality, high-performance substrates. This process is designed to leverage the advanced material properties of the ISOLAI I SPEED substrate and ensure that it meets the rigorous standards required for modern electronic applications.

- Material Preparation:The fabrication process begins with the preparation of the raw materials. This typically involves selecting high-grade ceramic or composite materials for the core layers, which are chosen for their thermal conductivity and electrical insulation properties. Metal layers, such as copper, are also prepared for integration into the substrate.

- Layer Deposition:The substrate’s core layers are deposited using techniques such as lamination or screen printing. In the case of ISOLAI I SPEED, this often involves applying a thin layer of ceramic or composite material onto a base material. Metal layers are then applied to the core, usually through processes like sputtering or electroplating, to create conductive pathways and support circuitry.

- Patterning: Once the layers are deposited, the next step is to pattern them according to the substrate design. This involves creating precise circuit patterns and vias using photolithography or laser etching. The patterning process defines the electrical pathways and ensures that the substrate meets the design specifications.

- Etching and Cleaning: After patterning, the substrate undergoes etching to remove unwanted material and reveal the final circuit patterns. This step is followed by a cleaning process to ensure that all residues and contaminants are removed, preparing the substrate for subsequent steps.

- Lamination and Bonding:The patterned substrate layers are then laminated together to form the final substrate structure. This may involve applying heat and pressure to bond the layers securely. For substrates with multiple layers, this process is repeated to build up the complete substrate stack-up.

- Inspection and Testing:The fabricated substrate undergoes rigorous inspection and testing to ensure it meets quality and performance standards. This includes visual inspections, electrical tests, and thermal performance evaluations. Any defects or inconsistencies are addressed before the substrate proceeds to final processing.

- Final Processing: The final processing steps include any additional treatments or coatings required for the substrate’s intended application. This may involve adding protective layers, surface treatments, or other modifications to enhance the substrate’s performance and durability.

- Cutting and Packaging:The completed substrates are cut to the required sizes and packaged for shipment. This step ensures that the substrates are delivered in optimal condition for integration into electronic systems.

The ISOLAI I SPEED substrate fabrication process is designed to produce high-performance substrates that excel in thermal management, signal integrity, and mechanical stability. Each step is carefully controlled to ensure that the final product meets the high standards required for advanced electronic applications.

The application of ceramic ISOLAI I SPEED Substrate

The ceramic ISOLAI I SPEED substrate is utilized in various high-performance electronic applications due to its superior thermal, electrical, and mechanical properties. These substrates are particularly valued in environments where reliability and efficiency are critical. Here are some of the key applications:

- Telecommunications:In telecommunications, the ISOLAI I SPEED substrate is used in high-frequency RF circuits and antennas. Its low dielectric loss and high thermal conductivity make it ideal for maintaining signal integrity and managing heat in high-speed communication systems. This ensures reliable performance in both consumer and professional telecommunications equipment.

- High-Speed Computing:The substrate is employed in high-speed computing applications, including processors and memory modules. The substrate’s excellent thermal management capabilities help dissipate heat generated by high-performance components, ensuring stable operation and preventing thermal throttling.

- Power Electronics:In power electronics, such as power converters and inverters, the ISOLAI I SPEED substrate’s high thermal conductivity is crucial for managing the heat produced by high-power devices. This helps in maintaining efficiency and extending the lifespan of power electronic components.

- Automotive Electronics:The substrate is used in automotive electronics where high reliability and durability are essential. Applications include engine control units (ECUs), sensors, and infotainment systems. The substrate’s ability to withstand harsh environmental conditions and manage heat makes it suitable for automotive applications.

- Aerospace and Defense:In aerospace and defense sectors, ISOLAI I SPEED substrates are used in avionics, radar systems, and other critical components. The substrate’s high thermal and electrical performance, along with its mechanical stability, ensures reliable operation in demanding environments.

- Medical Devices:The substrate finds applications in medical devices that require precise and reliable electronic components. Its properties support high-frequency medical imaging systems and other diagnostic equipment, where signal integrity and thermal management are crucial.

- Consumer Electronics:ISOLAI I SPEED substrates are also used in high-end consumer electronics such as smartphones, tablets, and advanced wearables. The substrate’s performance ensures high-speed data transmission and effective heat dissipation in compact devices.

Overall, the ceramic ISOLAI I SPEED substrate is applied in diverse fields where advanced thermal management, signal integrity, and mechanical reliability are essential. Its high performance and versatility make it a valuable component in modern electronic systems across various industries.

FAQs about ISOLAI I SPEED Substrate

What are the main advantages of ISOLAI I SPEED Substrate?

The main advantages include excellent heat dissipation, high signal integrity, mechanical stability, and durability. It is suitable for high-speed, high-power, and high-frequency applications.

What materials are used in ISOLAI I SPEED Substrate?

The substrate typically uses high-grade ceramic or composite materials for the core and metal layers, such as copper, for electrical conductivity.

What applications are suitable for ISOLAI I SPEED Substrate?

It is used in telecommunications, high-speed computing, power electronics, automotive electronics, aerospace and defense, medical devices, and consumer electronics.

How is ISOLAI I SPEED Substrate fabricated?

The fabrication process involves material preparation, layer deposition, patterning, etching, lamination, inspection, and final processing to create high-performance substrates.

How does ISOLAI I SPEED Substrate manage thermal issues?

Its high thermal conductivity helps dissipate heat efficiently, preventing overheating and ensuring stable performance in high-power applications.

Is ISOLAI I SPEED Substrate durable?

Yes, it is designed to be durable and resistant to environmental factors, making it suitable for demanding applications where reliability is crucial.

Your Website Name

Your Website Name