ISOLA IS550H Substrate Manufacturer

ISOLA IS550H Substrate Manufacturer,ISOLA IS550H is a high-performance substrate designed for demanding electronic applications. It features excellent thermal stability and electrical insulation properties, making it suitable for high-frequency and high-speed circuits. The substrate is known for its low dielectric loss and consistent dielectric constant, which ensure reliable signal integrity and reduced signal attenuation. Its robust thermal conductivity supports efficient heat dissipation, enhancing the overall performance and reliability of electronic devices. ISOLA IS550H is ideal for use in advanced electronic packaging and high-performance applications, offering both durability and superior performance.

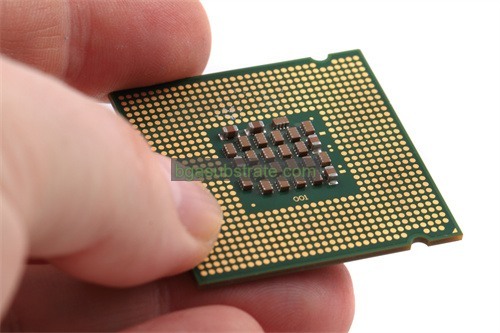

What is ISOLA IS550H Substrate?

The ISOLA IS550H substrate is a high-performance laminate material used in the fabrication of printed circuit boards (PCBs). This substrate is part of Isola’s line of advanced laminate materials, designed to meet the stringent demands of modern electronic applications.

IS550H is particularly notable for its exceptional thermal and electrical properties. It features a high glass transition temperature (Tg), which indicates its ability to withstand elevated temperatures without significant degradation of its mechanical properties. This makes it suitable for use in high-temperature applications where thermal stability is crucial.

The substrate is composed of a composite of resin and reinforcing fibers, which are engineered to provide high dimensional stability and low coefficient of thermal expansion (CTE). These characteristics are essential for ensuring the reliability and performance of the PCB, especially in applications that involve thermal cycling or high-power dissipation.

In addition to its thermal properties, IS550H offers excellent electrical performance, including low dielectric loss and high dielectric strength. These properties contribute to the efficient transmission of signals and reduce signal degradation, which is particularly important in high-frequency and high-speed digital applications.

Overall, ISOLA IS550H substrates are designed to meet the demanding requirements of advanced electronic systems, including those used in telecommunications, automotive, and high-performance computing. The material’s combination of thermal stability, electrical performance, and mechanical strength makes it a popular choice for manufacturers looking to produce reliable and high-quality PCBs.

ISOLA IS550H Substrate Manufacturer

What is the ISOLA IS550H Substrate Design Guidelines?

The ISOLA IS550H substrate design guidelines provide crucial information for engineers and designers to ensure optimal performance and reliability of PCBs fabricated with this advanced laminate material. These guidelines are essential for leveraging the full capabilities of IS550H and achieving high-quality results in electronic applications.

- Thermal Management: IS550H substrates are designed to handle high temperatures, but proper thermal management is still crucial. Ensure that the PCB design includes adequate heat dissipation features such as heat sinks, thermal vias, or copper pours to manage heat generated during operation. This helps maintain the integrity of the substrate and the performance of the electronic components.

- Layer Stack-Up: Pay careful attention to the layer stack-up in your PCB design. IS550H is compatible with various layer configurations, but it is essential to optimize the stack-up to balance electrical performance and mechanical stability. Ensure proper alignment and bonding of layers to avoid issues such as warping or delamination.

- Clearance and Spacing: Adhere to the recommended clearance and spacing guidelines to prevent electrical interference and ensure reliability. IS550H substrates offer excellent electrical performance, but maintaining appropriate spacing between traces, vias, and components helps prevent signal degradation and crosstalk.

- Via Design: When designing vias, consider the substrate’s thermal and electrical properties. Use appropriate via sizes and plating techniques to ensure reliable electrical connections and thermal conduction. IS550H’s low CTE helps mitigate issues related to via thermal cycling.

- Copper Thickness: Select the appropriate copper thickness for your design needs. IS550H substrates support various copper thicknesses, and choosing the right thickness helps optimize the substrate’s thermal and electrical performance.

- Testing and Inspection: Implement rigorous testing and inspection procedures to verify the integrity of the PCB. IS550H’s performance can be influenced by factors such as fabrication quality and handling, so thorough testing ensures that the final product meets the required specifications.

By following these design guidelines, you can maximize the benefits of ISOLA IS550H substrates and achieve reliable, high-performance PCBs for a wide range of advanced electronic applications.

The advantages of ISOLA IS550H Substrate

The ISOLA IS550H substrate offers several significant advantages that make it a preferred choice for high-performance printed circuit boards (PCBs) in advanced electronic applications. These advantages are crucial for achieving reliable and efficient performance in demanding environments.

- High Thermal Stability: IS550H features a high glass transition temperature (Tg), which allows it to maintain structural integrity and performance even at elevated temperatures. This thermal stability is essential for applications with high power dissipation or thermal cycling, reducing the risk of thermal-related failures.

- Excellent Electrical Performance:The substrate provides low dielectric loss and high dielectric strength, ensuring efficient signal transmission with minimal signal degradation. These electrical properties are particularly beneficial for high-frequency and high-speed digital circuits, where signal integrity is critical.

- Low Coefficient of Thermal Expansion (CTE): IS550H has a low CTE, which helps minimize the expansion and contraction of the PCB with temperature changes. This characteristic reduces the risk of warping, delamination, and mechanical stress on solder joints, contributing to the long-term reliability of the PCB.

- High Dimensional Stability: The substrate’s design ensures minimal dimensional changes during thermal cycling, which helps maintain the accuracy and reliability of the PCB layout. This stability is crucial for ensuring consistent performance and alignment of electronic components.

- Enhanced Mechanical Strength: IS550H substrates offer robust mechanical properties, providing durability and resistance to mechanical stresses. This strength is important for maintaining the structural integrity of the PCB in various operating conditions, including high-vibration environments.

- Compatibility with Advanced Manufacturing Processes: IS550H is compatible with a range of advanced PCB manufacturing processes, including those used for high-density interconnect (HDI) boards. This compatibility facilitates the production of complex and high-performance PCBs.

- Versatility in Applications: The substrate’s combination of thermal, electrical, and mechanical properties makes it suitable for a wide range of applications, including telecommunications, automotive electronics, and high-performance computing.

Overall, the ISOLA IS550H substrate’s advantages in thermal stability, electrical performance, dimensional stability, and mechanical strength make it an excellent choice for designing reliable and high-performing PCBs in advanced electronic systems.

What is the ISOLA IS550H Substrate Fabrication Process?

The fabrication process for ISOLA IS550H substrates involves several key steps to ensure the production of high-quality printed circuit boards (PCBs) with optimal performance. The process is designed to take advantage of the substrate’s advanced properties, including thermal stability, electrical performance, and dimensional accuracy.

- Material Preparation: The IS550H substrate starts as a laminate material consisting of a resin-impregnated fiberglass fabric. This laminate is pre-impregnated (prepreg) and prepared to meet specific thermal and electrical properties required for high-performance applications.

- Layer Stacking: The fabrication process begins with stacking the laminate layers according to the desired PCB design. Each layer is carefully aligned to ensure accurate registration and bonding. The layer stack-up is critical for achieving the required electrical performance and mechanical stability.

- Lamination:The stacked layers are subjected to a lamination process, where heat and pressure are applied to bond the layers together. This process cures the resin and forms a solid, homogeneous substrate. The high glass transition temperature (Tg) of IS550H ensures that the substrate retains its mechanical and thermal properties throughout this process.

- Drilling: After lamination, the substrate undergoes drilling to create holes for vias, component leads, and other electrical connections. Precision drilling is essential to maintain the substrate’s dimensional stability and ensure accurate placement of electronic components.

- Imaging and Etching: The PCB design is transferred onto the substrate using imaging techniques, such as photolithography. A light-sensitive photoresist layer is applied, and the design is exposed and developed to create a pattern. The exposed copper areas are then etched away, leaving behind the desired circuit traces and pads.

- Plating: The drilled holes and etched traces are plated with copper to ensure electrical connectivity. This process involves depositing a thin layer of copper onto the exposed surfaces and within the vias. Additional plating steps may be used to achieve the required thickness and conductivity.

- Solder Mask and Surface Finish: A solder mask layer is applied to protect the copper traces from oxidation and to prevent solder bridges during component assembly. Various surface finishes, such as immersion gold or HASL (Hot Air Solder Leveling), may be applied to enhance solderability and protect the exposed copper.

- Component Assembly: Once the substrate is fabricated, electronic components are mounted and soldered onto the PCB. This assembly process involves placing components onto the substrate and soldering them in place using techniques such as reflow soldering or wave soldering.

- Testing and Inspection: The final PCB undergoes rigorous testing and inspection to ensure it meets the required specifications. This includes electrical testing, visual inspection, and other quality control measures to verify the functionality and reliability of the substrate.

By following these steps, the ISOLA IS550H substrate is fabricated to meet the high standards required for advanced electronic applications, ensuring reliable performance and durability.

The application of ceramic ISOLA IS550H Substrate

Ceramic substrates, such as ISOLA IS550H, are utilized in various high-performance and demanding applications due to their unique properties. Here’s an overview of the key applications for ceramic ISOLA IS550H substrates:

- Telecommunications: In telecommunications, IS550H substrates are used in high-frequency and high-speed circuits. Their low dielectric loss and excellent electrical performance make them ideal for RF (Radio Frequency) and microwave applications, including base stations, antennas, and signal processing equipment.

- Automotive Electronics: The automotive industry relies on IS550H substrates for applications that require high thermal stability and reliability. These include advanced driver-assistance systems (ADAS), infotainment systems, and power management modules. The substrate’s ability to handle high temperatures and resist thermal cycling is crucial in automotive environments.

- High-Performance Computing: In high-performance computing systems, IS550H substrates are used for high-speed data transmission and processing. Their low coefficient of thermal expansion (CTE) and excellent dimensional stability help ensure reliable performance and signal integrity in complex computing hardware, such as servers and data centers.

- Industrial Equipment: For industrial applications, IS550H substrates are employed in various types of equipment, including control systems, power supplies, and instrumentation. The substrate’s robust mechanical properties and thermal management capabilities make it suitable for demanding industrial environments.

- Medical Devices: In the medical field, IS550H substrates are used in high-precision medical equipment, including diagnostic machines and monitoring systems. The substrate’s thermal stability and electrical performance contribute to the reliability and accuracy of medical devices.

- Aerospace and Defense: Aerospace and defense applications require substrates that can withstand extreme conditions and provide consistent performance. IS550H substrates are used in avionics, satellite systems, and military electronics due to their high thermal resistance, dimensional stability, and reliability under harsh conditions.

- Power Electronics: IS550H substrates are utilized in power electronics for applications such as power converters, inverters, and motor drives. The substrate’s thermal management capabilities and mechanical strength are essential for handling high power levels and ensuring long-term reliability.

- Consumer Electronics: Although less common, IS550H substrates can also be found in high-end consumer electronics where advanced performance and durability are required, such as high-resolution displays and premium audio equipment.

In summary, the ISOLA IS550H ceramic substrate is valued for its high thermal stability, excellent electrical performance, and robust mechanical properties, making it suitable for a wide range of advanced and demanding applications across various industries.

FAQs about ISOLA IS550H Substrate

What are the main advantages of ISOLA IS550H?

The main advantages include high thermal stability, low dielectric loss, low coefficient of thermal expansion (CTE), excellent mechanical strength, and compatibility with advanced manufacturing processes.

What types of applications are suitable for ISOLA IS550H?

ISOLA IS550H is suitable for high-frequency and high-speed applications, including telecommunications, automotive electronics, high-performance computing, industrial equipment, medical devices, aerospace, and defense.

What is the thermal stability of ISOLA IS550H?

ISOLA IS550H has a high glass transition temperature (Tg), making it capable of withstanding high temperatures without significant degradation, ideal for applications involving thermal cycling and high power dissipation.

How does ISOLA IS550H perform in terms of electrical properties?

The substrate offers low dielectric loss and high dielectric strength, ensuring efficient signal transmission and minimal signal degradation, which is crucial for high-speed and high-frequency circuits.

What is the coefficient of thermal expansion (CTE) of ISOLA IS550H?

ISOLA IS550H has a low CTE, which helps reduce expansion and contraction with temperature changes, minimizing warping and mechanical stress on the PCB.

Can ISOLA IS550H be used for high-density interconnect (HDI) boards?

Yes, IS550H is compatible with various advanced PCB manufacturing processes, including those for high-density interconnect (HDI) boards.

Your Website Name

Your Website Name