ISOLA IS420 Substrate Manufacturer

ISOLA IS420 Substrate Manufacturer,ISOLA IS420 is a high-performance substrate material designed for advanced electronic applications. It boasts excellent electrical characteristics, including a low dielectric constant and low loss tangent, which ensure superior signal integrity and minimal signal degradation. The substrate provides outstanding thermal stability and mechanical strength, making it suitable for complex, high-layer-count PCB designs. IS420 is also known for its resistance to high temperatures and thermal cycling, enhancing its reliability in challenging environments. Ideal for telecommunications, automotive, and high-speed digital systems, ISOLA IS420 combines robust performance with durability, making it a preferred choice for cutting-edge electronic applications.

What is ISOLA IS420 Substrate?

The ISOLA IS420 substrate is a high-performance laminate material designed for use in advanced printed circuit boards (PCBs). It is part of Isola’s IS400 series, known for its exceptional thermal, electrical, and mechanical properties. The IS420 substrate is particularly noted for its suitability in high-frequency applications, including RF and microwave circuit boards.

One of the key features of IS420 is its low dielectric loss, which ensures minimal signal degradation and high performance in demanding electronic environments. Its dielectric constant is stable across a wide frequency range, which helps in maintaining consistent electrical characteristics and reducing signal distortion. This stability makes it ideal for applications requiring precise signal transmission and minimal signal loss.

The substrate is also known for its excellent thermal conductivity, which is crucial in managing heat dissipation in high-power applications. This thermal performance contributes to the overall reliability and longevity of the PCBs manufactured with IS420. Additionally, IS420 offers good mechanical stability and can withstand various environmental conditions, ensuring durability and robustness in various applications.

IS420 is widely used in high-frequency circuit applications such as telecommunications, aerospace, and defense systems. Its advanced material properties make it a preferred choice for manufacturers looking to achieve high performance and reliability in their electronic designs.

Overall, ISOLA IS420 substrates provide an effective solution for modern electronic devices that demand high-frequency performance, reliability, and thermal management.

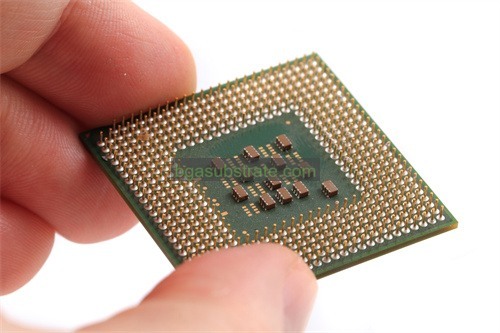

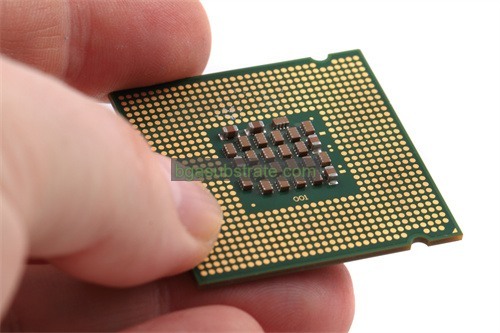

ISOLA IS420 Substrate Manufacturer

What is the ISOLA IS420 Substrate Design Guidelines?

The ISOLA IS420 substrate design guidelines offer essential recommendations to ensure optimal performance and reliability when using this high-frequency laminate material in printed circuit board (PCB) applications. Here are key aspects to consider:

- Material Properties: IS420 substrates are designed for high-frequency applications, so it’s important to account for their low dielectric loss and stable dielectric constant. This ensures minimal signal degradation and consistent electrical performance. When designing circuits, consider the dielectric constant (Dk) and loss tangent (Df) provided by Isola for accurate signal integrity analysis.

- Layer Stack-Up: Proper layer stack-up design is crucial for maintaining signal integrity and minimizing crosstalk. The IS420 substrate’s performance can be optimized by carefully designing the PCB stack-up, including the arrangement of signal layers, dielectric layers, and ground planes. Ensure that the dielectric thicknesses align with the required impedance control and signal propagation characteristics.

- Impedance Control: Achieving accurate impedance control is vital for high-frequency designs. Utilize impedance calculators and tools to determine the appropriate trace width and spacing for the desired impedance. IS420’s consistent dielectric properties help maintain impedance stability, but careful design practices are still necessary.

- Thermal Management: IS420 substrates offer good thermal conductivity, but effective heat dissipation strategies are essential for high-power applications. Design the PCB with adequate thermal vias, heat sinks, or other cooling mechanisms to manage heat and prevent thermal stress on the substrate.

- Manufacturing Considerations: Ensure that the PCB design adheres to the fabrication capabilities and limitations of IS420 substrates. Pay attention to parameters such as minimum trace width, spacing, and drill sizes to avoid issues during manufacturing and assembly.

- Environmental Protection: Consider the environmental conditions in which the PCB will operate. Although IS420 substrates offer good mechanical stability, additional protective measures such as conformal coatings may be necessary to safeguard against moisture, chemicals, or other environmental factors.

By following these design guidelines, you can leverage the advanced properties of ISOLA IS420 substrates to create high-performance PCBs for demanding high-frequency applications.

The advantages of ISOLA IS420 Substrate

The ISOLA IS420 substrate offers several advantages that make it a preferred choice for high-performance printed circuit board (PCB) applications, particularly in high-frequency and high-power environments. Here are the key benefits:

- Low Dielectric Loss: IS420 substrates feature a low dielectric loss (Df), which reduces signal attenuation and degradation, ensuring high signal integrity and minimal performance loss. This characteristic is essential for maintaining the quality and reliability of high-frequency signals.

- Stable Dielectric Constant: The substrate provides a stable dielectric constant (Dk) across a wide frequency range. This stability helps in achieving consistent impedance control and reliable signal transmission, crucial for high-speed and high-frequency applications.

- High Thermal Conductivity: IS420 substrates are known for their excellent thermal conductivity, which aids in effective heat dissipation. This property is important for managing heat in high-power electronic devices, contributing to overall device longevity and performance.

- Mechanical Stability: The substrate offers good mechanical stability, ensuring that the PCB maintains its structural integrity under various environmental conditions. This stability helps in preventing warping or deformation, which can affect the performance and reliability of the PCB.

- Durability and Reliability: IS420 substrates are designed to withstand harsh environments, including high temperatures and mechanical stresses. This durability makes them suitable for demanding applications in telecommunications, aerospace, and defense sectors.

- Precision and Performance: With its advanced material properties, IS420 enables the creation of PCBs with precise dimensions and high performance. This precision is crucial for high-frequency circuits where signal integrity and accuracy are critical.

- Versatility: The substrate is versatile and can be used in a variety of applications, including RF and microwave circuits, due to its superior electrical and thermal properties. This flexibility makes it a valuable material for diverse high-frequency electronic designs.

Overall, ISOLA IS420 substrates offer a combination of low dielectric loss, stable dielectric constant, high thermal conductivity, and mechanical stability, making them an excellent choice for high-performance and reliable PCB applications.

What is the ISOLA IS420 Substrate Fabrication Process?

The ISOLA IS420 is a high-performance laminate material used in printed circuit boards (PCBs). The fabrication process for ISOLA IS420 involves several key steps:

- Material Preparation: The process begins with the preparation of the IS420 laminate material, which typically consists of a resin system combined with a woven glass fabric. The resin is usually a type of epoxy with high thermal and electrical performance characteristics.

- Lamination: The prepared resin and glass fabric are layered and then subjected to high pressure and temperature in a lamination press. This step cures the resin and bonds the glass fabric together, creating a solid laminate with the desired thickness and properties.

- Drilling: Once the laminate is cured, it is drilled to create holes for vias and through-holes, which are essential for electrical connections between different layers of the PCB.

- Copper Cladding: The drilled laminate is then coated with a thin layer of copper, which will serve as the conductive paths for the electrical signals. This is done through a process called electroplating or by using pre-clad copper.

- Etching: The copper-coated laminate is exposed to an etching solution that removes unwanted copper, leaving behind the desired circuit patterns. This step defines the circuit traces and pads on the PCB.

- Layering and Bonding: For multi-layer PCBs, additional layers of IS420 laminate and copper are added and bonded together. This may involve additional lamination steps to ensure strong adhesion between layers.

- Testing and Quality Control: After fabrication, the PCB is tested for electrical integrity and other performance characteristics. This includes checking for any defects in the copper patterns, ensuring that all vias are properly connected, and verifying that the board meets the required specifications.

- Finishing: The final steps include applying a protective coating, such as solder mask, and adding any other necessary surface finishes or components.

The ISOLA IS420 substrate is known for its high thermal stability, low dielectric loss, and excellent electrical performance, making it suitable for demanding applications in telecommunications, automotive, and other high-tech industries.

The application of ceramic ISOLA IS420 Substrate

The ISOLA IS420 substrate, primarily used in high-performance PCB applications, has several specialized applications in the electronics industry. Here’s an overview of its applications:

- High-Frequency Electronics: Due to its low dielectric loss and high thermal stability, IS420 is commonly used in high-frequency and microwave applications. It helps maintain signal integrity and minimize signal degradation in communication systems, including RF circuits and satellite communications.

- Telecommunications: In telecommunications, IS420 substrates are used for advanced network equipment, including base stations and routers. Their high performance ensures reliable data transmission and reception in complex and demanding environments.

- Automotive Electronics: The IS420 substrate is utilized in automotive applications where reliability and durability are critical. It is used in various automotive systems such as advanced driver-assistance systems (ADAS), infotainment systems, and engine control units (ECUs) due to its robustness and ability to withstand high temperatures.

- Aerospace and Defense: The aerospace and defense sectors benefit from IS420 substrates because of their high thermal and mechanical stability. They are used in avionics systems, radar equipment, and other critical applications where performance and reliability are essential.

- Consumer Electronics: In consumer electronics, IS420 substrates are used in high-performance devices such as smartphones, tablets, and gaming consoles. The substrate’s low loss and high thermal conductivity contribute to the overall performance and longevity of these devices.

- Medical Devices:IS420 substrates are also used in medical electronics where precision and reliability are crucial. Applications include diagnostic equipment, monitoring devices, and other medical instrumentation.

- Power Electronics: The substrate’s ability to handle high power levels makes it suitable for power electronics applications, including power supplies, converters, and inverters, where efficient heat dissipation and electrical performance are required.

Overall, the ISOLA IS420 substrate’s exceptional electrical properties, thermal stability, and mechanical strength make it suitable for a wide range of demanding applications across various industries.

FAQs

What is ISOLA IS420?

ISOLA IS420 is a high-performance laminate material used in printed circuit boards (PCBs) known for its low dielectric loss, high thermal stability, and excellent electrical performance.

Who are the manufacturers of ISOLA IS420 substrates?

ISOLA Group is the primary manufacturer of IS420 substrates. They are known for producing high-quality laminates for various high-tech applications.

Where can I purchase ISOLA IS420 substrates?

ISOLA IS420 substrates can be purchased directly from ISOLA Group or through authorized distributors and suppliers who specialize in PCB materials.

What are the key applications of ISOLA IS420 substrates?

ISOLA IS420 substrates are used in high-frequency electronics, telecommunications, automotive systems, aerospace and defense, consumer electronics, medical devices, and power electronics.

What are the benefits of using ISOLA IS420 substrates?

The benefits include low dielectric loss, high thermal stability, excellent electrical performance, and robustness, making it suitable for demanding applications.

What certifications does ISOLA IS420 have?

ISOLA IS420 substrates typically meet industry standards and certifications, including UL certification for flammability and RoHS compliance for environmental safety.

Your Website Name

Your Website Name