ISOLA IS410 Substrate Manufacturer

ISOLA IS410 Substrate Manufacturer,ISOLA IS410 is a high-performance substrate material engineered for demanding PCB applications. It features exceptional electrical properties, including a low dielectric constant and low dissipation factor, which ensure superior signal integrity and minimal signal loss. The substrate offers excellent thermal stability and mechanical strength, making it suitable for complex, high-layer-count circuit boards. IS410 is also known for its resistance to thermal cycling and high temperatures, enhancing reliability in various electronic environments. Ideal for use in telecommunications, automotive, and high-speed digital applications, ISOLA IS410 delivers robust performance and durability for advanced electronic systems.

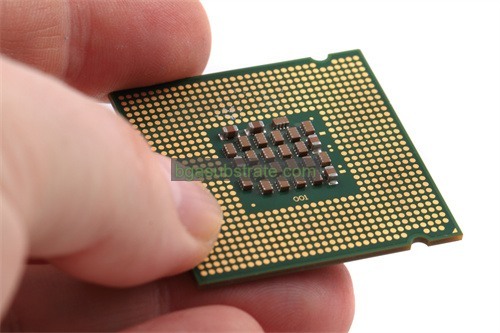

What is ISOLA IS410 Substrate ?

ISOLA IS410 is a high-performance laminate material designed for use in printed circuit boards (PCBs) that require superior electrical and mechanical properties. Developed by ISOLA Group, a prominent name in the PCB materials industry, IS410 is a type of advanced epoxy-based laminate specifically engineered for high-frequency and high-speed applications.

The IS410 substrate is known for its excellent electrical performance, including low dielectric constant (Dk) and low dielectric loss (Df), which are crucial for minimizing signal degradation and maintaining signal integrity in high-speed digital and RF (radio frequency) applications. These properties make IS410 suitable for use in high-speed computing, telecommunications, and sophisticated electronic systems where high-frequency signal transmission is critical.

In addition to its electrical performance, IS410 offers strong thermal stability, which is essential for managing heat dissipation in densely packed PCBs. Its robust mechanical properties, including good dimensional stability and durability, ensure that it can withstand the stresses of modern manufacturing processes and operating conditions.

IS410 also features low moisture absorption, which helps maintain its electrical properties over time and under varying environmental conditions. This makes it a reliable choice for demanding applications where long-term performance and reliability are key considerations.

Overall, ISOLA IS410 is a versatile and high-performing substrate that meets the needs of advanced electronic applications, providing a balance of electrical performance, thermal stability, and mechanical strength.

ISOLA IS410 Substrate Manufacturer

What is the ISOLA IS410 Substrate Design Guidelines?

The ISOLA IS410 is a high-performance laminate material used for PCB substrates, known for its excellent electrical and thermal properties. Here are some key design guidelines for using ISOLA IS410 substrates:

- Thermal Management: IS410 offers good thermal conductivity, but designers should still ensure proper heat dissipation. Adequate thermal vias and heat sinks may be required for high-power applications.

- Layer Stackup: Design the PCB layer stackup to optimize signal integrity and thermal performance. IS410 supports various stackups, but it’s important to account for the material’s CTE (Coefficient of Thermal Expansion) to minimize thermal stress.

- Impedance Control: IS410 provides good dielectric stability, making it suitable for high-speed and high-frequency applications. Ensure that trace impedance is controlled by following proper trace width and spacing guidelines.

- Via and Hole Design: When designing vias and through-holes, consider the thermal and electrical performance of the substrate. IS410’s properties allow for reliable performance, but design for appropriate via sizes and plating to maintain integrity.

- Fabrication Tolerances: Adhere to the recommended fabrication tolerances provided by ISOLA for IS410 to ensure manufacturability and performance. This includes dimensions for traces, pads, and clearances.

- Thermal Cycling: IS410 has good thermal cycling performance, but it’s still crucial to design for potential temperature variations. Consider the impact of thermal cycling on component reliability and substrate performance.

- Material Handling: Proper handling and storage of IS410 materials are essential to maintain their performance characteristics. Follow recommended guidelines to avoid damage or degradation of the laminate.

- Compliance and Testing: Ensure that the design complies with industry standards and perform necessary electrical and mechanical testing to validate the performance of the IS410 substrate in your application.

These guidelines help in leveraging the strengths of ISOLA IS410 for various high-performance applications while ensuring reliability and manufacturability.

The advantages of ISOLA IS410 Substrate

ISOLA IS410 substrate offers several advantages for high-performance PCB applications:

- High Thermal Conductivity: IS410 has excellent thermal conductivity, which helps in efficient heat dissipation and reduces the risk of thermal-related issues in high-power applications.

- Low Dielectric Loss: The substrate provides low dielectric loss, making it suitable for high-frequency and high-speed signal applications. This results in better signal integrity and reduced signal attenuation.

- Stable Electrical Properties: IS410 maintains stable electrical properties over a wide range of temperatures and frequencies, ensuring reliable performance in demanding applications.

- Good Thermal Cycling Performance: The material exhibits good thermal cycling performance, making it resilient to temperature variations and enhancing the reliability of the PCB.

- Low Coefficient of Thermal Expansion (CTE): IS410 has a low CTE, which reduces the risk of thermal stress and delamination between the PCB layers and components, especially in high-temperature environments.

- High Mechanical Strength: The substrate offers high mechanical strength and durability, which contributes to the structural integrity of the PCB and withstands mechanical stresses during assembly and operation.

- Compatibility with Lead-Free Soldering: IS410 is compatible with lead-free soldering processes, which aligns with environmental regulations and modern manufacturing practices.

- Excellent Processability: The material is designed to be easy to process, which can streamline PCB manufacturing and reduce production costs.

- Reliable Performance in Harsh Environments: IS410 can perform reliably in harsh environments, including high-temperature and high-humidity conditions, making it suitable for a wide range of applications.

These advantages make ISOLA IS410 a popular choice for high-speed, high-frequency, and high-power PCB applications, providing both performance and reliability.

What is the ISOLA IS410 Substrate Fabrication Process?

The fabrication process for ISOLA IS410 substrates involves several key steps to ensure high-quality performance and reliability. Here’s an overview of the typical fabrication process:

- Material Preparation: Start with ISOLA IS410 laminate material in the desired thickness. The laminate is typically available in sheets or rolls.

- Cutting and Laminating: Cut the IS410 laminate to the required size for the PCB. The laminate sheets are then laminated to a copper foil (or other conductive materials) using high temperature and pressure to ensure proper bonding.

- Drilling: Drill holes for vias, through-holes, and component placements. Precision drilling is crucial to ensure the holes align correctly and do not damage the substrate.

- Imaging and Etching: Apply a photoresist layer to the surface of the PCB. Use photolithography to transfer the circuit pattern onto the photoresist. The exposed areas are then developed and etched away to create the circuit traces on the copper foil.

- Plating: Electroplate or chemically plate the vias and through-holes to ensure proper electrical conductivity. This step may involve adding a thin layer of metal (such as copper) to the inner surfaces of the holes.

- Surface Finish: Apply a surface finish to protect the exposed copper and improve solderability. Common finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), or OSP (Organic Solderability Preservative).

- Cleaning and Inspection: Thoroughly clean the PCB to remove any residues from the fabrication process. Inspect the PCB for any defects or issues, such as misalignment, etching errors, or coating problems.

- Testing: Perform electrical and mechanical tests to verify the functionality and reliability of the PCB. Testing may include continuity checks, impedance measurements, and thermal cycling tests.

- Cutting and Finalizing: Cut the PCB to its final shape and size. Additional processes, such as mounting components and soldering, can then be performed as needed for the final assembly.

- Quality Control: Conduct final quality control checks to ensure the PCB meets all specifications and performance requirements. This may include visual inspections and automated tests.

By following these steps, manufacturers can effectively produce ISOLA IS410 substrates that meet high standards of performance and reliability for various applications.

The application of ceramic ISOLA IS410 Substrate

Ceramic substrates, including ISOLA IS410, are utilized in various advanced electronic and industrial applications due to their superior properties. Here’s a look at the primary applications of ceramic ISOLA IS410 substrates:

- High-Frequency and High-Speed Circuits: ISOLA IS410’s low dielectric loss and stable electrical properties make it ideal for high-frequency and high-speed electronic applications, such as RF (Radio Frequency) and microwave circuits.

- Power Electronics: The high thermal conductivity of IS410 is beneficial for power electronics, where efficient heat dissipation is critical. It is used in power amplifiers, power converters, and other high-power electronic devices.

- Aerospace and Defense: In aerospace and defense applications, where reliability and performance under extreme conditions are crucial, IS410’s durability and thermal stability make it suitable for use in various electronic systems and components.

- Automotive Electronics: IS410 is used in automotive electronics where high thermal and mechanical stability is required, such as in engine control units (ECUs), powertrain control systems, and other critical automotive components.

- Telecommunications:The substrate’s excellent electrical performance is used in telecommunications infrastructure, including base stations, network equipment, and signal processing modules.

- Medical Devices: IS410’s reliability and performance under demanding conditions make it suitable for medical devices and equipment, where precise and consistent operation is necessary.

- Consumer Electronics: High-performance consumer electronics, including advanced computing devices and consumer gadgets, benefit from the thermal and electrical properties of IS410 for improved performance and longevity.

- Industrial Control Systems: In industrial applications, IS410 is used in control systems and automation equipment that require robust and reliable performance under varying environmental conditions.

- Military Applications: Due to its reliability and ability to operate under harsh conditions, IS410 is used in military electronics and systems, including communication systems and navigational equipment.

These applications leverage ISOLA IS410’s advantages in terms of thermal management, electrical stability, and mechanical strength, making it a versatile choice for a wide range of high-performance electronic systems.

FAQs

What is ISOLA IS410?

ISOLA IS410 is a high-performance laminate material used for PCB substrates, known for its excellent thermal and electrical properties.

What are the main advantages of ISOLA IS410?

High thermal conductivity, low dielectric loss, stable electrical properties, good thermal cycling performance, and compatibility with lead-free soldering.

What applications is ISOLA IS410 suitable for?

It is ideal for high-frequency and high-speed circuits, power electronics, aerospace, automotive, telecommunications, medical devices, consumer electronics, and industrial control systems.

How does ISOLA IS410 perform under thermal cycling?

IS410 has good thermal cycling performance, making it resilient to temperature variations and reducing the risk of thermal stress-related issues.

What is the typical fabrication process for ISOLA IS410 substrates?

The process includes material preparation, cutting, laminating, drilling, imaging and etching, plating, surface finishing, cleaning, inspection, testing, and finalizing.

What is the recommended layer stackup for ISOLA IS410?

The layer stackup should be designed to optimize signal integrity and thermal performance, considering the material’s CTE and electrical properties.

Your Website Name

Your Website Name