ISOLA I-TERA® MT40 (RF/MW) Substrate Manufacturer

ISOLA I-TERA® MT40 (RF/MW) Substrate Manufacturer,ISOLA I-TERA® MT40 (RF/MW) is an advanced substrate material designed for high-frequency and microwave applications. It features exceptional electrical properties, including a low dielectric constant and low loss tangent, which ensure superior signal integrity and reduced signal attenuation at RF and microwave frequencies. The substrate’s excellent thermal stability and mechanical strength support complex, high-performance circuit designs in demanding environments. Additionally, I-TERA® MT40 (RF/MW) is halogen-free, aligning with eco-friendly manufacturing standards. Ideal for telecommunications, aerospace, and high-speed data applications, this substrate combines high-performance characteristics with sustainability, making it a top choice for cutting-edge RF and microwave systems.

What is ISOLA I-TERA® MT40 (RF/MW) Substrate?

ISOLA I-TERA® MT40 (RF/MW) is a high-performance substrate material designed specifically for high-frequency applications in the RF (Radio Frequency) and MW (Microwave) domains. This substrate is engineered to meet the stringent demands of advanced communication systems, including those used in mobile devices, satellite communications, and radar systems.

One of the key features of I-TERA® MT40 is its low dielectric loss tangent, which minimizes signal attenuation and ensures high signal integrity. This characteristic is crucial for maintaining signal clarity and strength in high-frequency applications. Additionally, the substrate has a high thermal conductivity, which helps in efficiently dissipating heat generated by high-power RF components, thereby enhancing the overall reliability and performance of the electronic devices.

The material is typically composed of a modified epoxy resin system, which provides excellent electrical performance while maintaining good mechanical strength and durability. It offers a controlled dielectric constant (Dk) and low coefficient of thermal expansion (CTE), which are essential for maintaining dimensional stability and precise electrical performance in varying environmental conditions.

ISOLA I-TERA® MT40 is often used in applications such as RF circuit boards, microwave circuits, and high-speed digital applications where signal integrity and thermal management are critical. Its advanced properties make it a suitable choice for demanding applications that require high-frequency performance and reliability.

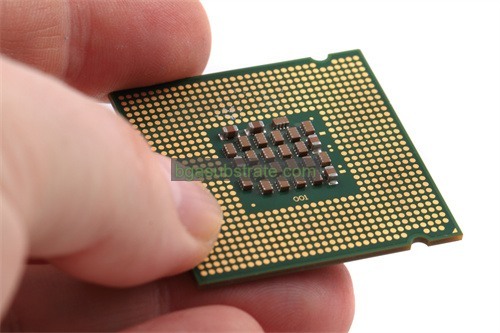

ISOLA I-TERA® MT40 (RF/MW) Substrate Manufacturer

What is the ISOLA I-TERA® MT40 (RF/MW) Substrate Design Guidelines?

Designing with ISOLA I-TERA® MT40 (RF/MW) substrates involves several key guidelines to optimize performance and ensure reliability in high-frequency applications. Here are some important design considerations:

- Impedance Control: Accurate impedance control is crucial for maintaining signal integrity at RF and microwave frequencies. Ensure that trace widths, spacing, and the dielectric thickness are carefully calculated and controlled to achieve the desired impedance values.

- Signal Routing: Minimize the length of high-frequency signal traces to reduce signal loss and avoid unnecessary complexity. Use short, direct routing paths to maintain signal integrity and minimize interference.

- Thermal Management: Given the high thermal conductivity of I-TERA® MT40, it’s important to incorporate adequate heat dissipation mechanisms in your design. Ensure that heat-sensitive components are properly cooled and that heat can be efficiently conducted away from critical areas.

- Via Design: When using vias, ensure that they are appropriately sized and spaced to avoid introducing unwanted inductance or capacitance. For high-frequency applications, consider using blind or buried vias to reduce signal loss.

- Layer Stackup: Carefully design the layer stackup to optimize the electrical performance and thermal management of the substrate. Pay attention to the thickness of dielectric layers and the alignment of different layers to maintain signal integrity.

- Ground Planes:Implement solid and continuous ground planes to provide a low-impedance return path for high-frequency signals. This helps to minimize noise and interference in your design.

- Testing and Validation: Perform thorough testing and validation of your design, including signal integrity analysis and thermal testing, to ensure that the substrate performs as expected under operational conditions.

By adhering to these design guidelines, you can effectively leverage the advanced properties of ISOLA I-TERA® MT40 to create reliable and high-performance RF and microwave circuits.

The advantages of ISOLA I-TERA® MT40 (RF/MW) Substrate

ISOLA I-TERA® MT40 (RF/MW) substrate offers several significant advantages, making it a preferred choice for high-frequency applications in RF and microwave domains:

- Low Dielectric Loss: The substrate features a low dielectric loss tangent, which reduces signal attenuation and ensures minimal signal degradation. This characteristic is critical for maintaining high signal integrity in RF and microwave circuits.

- High Thermal Conductivity:I-TERA® MT40 has excellent thermal conductivity, which facilitates effective heat dissipation from high-power RF components. This property helps in preventing overheating and enhances the overall reliability and longevity of electronic devices.

- Controlled Dielectric Constant (Dk): The substrate provides a stable and controlled dielectric constant, which is essential for precise impedance control and maintaining consistent electrical performance across varying frequencies.

- Low Coefficient of Thermal Expansion (CTE): The low CTE of I-TERA® MT40 ensures dimensional stability under varying temperature conditions. This property helps in maintaining the accuracy of the circuit’s performance and reduces the risk of thermal-induced warping or misalignment.

- Enhanced Signal Integrity: Due to its high-performance material properties, I-TERA® MT40 supports high-frequency signals with minimal interference and crosstalk, ensuring clean and reliable signal transmission.

- Mechanical Strength: The substrate offers good mechanical strength and durability, making it suitable for demanding environments where physical robustness is required.

- Versatility: I-TERA® MT40 can be used in a wide range of applications, including mobile communications, satellite systems, radar, and other high-frequency electronic devices, providing flexibility in design and application.

Overall, the advantages of ISOLA I-TERA® MT40 make it a highly effective substrate material for advanced RF and microwave applications, contributing to improved performance, reliability, and efficiency in electronic systems.

What is the ISOLA I-TERA® MT40 (RF/MW) Substrate Fabrication Process?

The fabrication process for ISOLA I-TERA® MT40 (RF/MW) substrate involves several key steps to ensure high-quality production of this advanced material. Here’s an overview of the typical fabrication process:

- Material Preparation: The process begins with the preparation of the I-TERA® MT40 resin and filler materials. These materials are carefully mixed to achieve the desired dielectric properties, including low dielectric loss and controlled dielectric constant.

- Lamination: The mixed resin is applied to copper foil or other conductive layers to form the laminate. This is done using a lamination process where heat and pressure are applied to bond the resin to the copper, creating a uniform and stable substrate layer.

- Curing: The laminate is then subjected to a curing process to harden the resin and ensure that it achieves its final mechanical and electrical properties. Curing involves heating the laminate to a specific temperature for a set period, allowing the resin to fully polymerize and stabilize.

- Drilling and Via Formation:After curing, the substrate undergoes drilling to create vias for electrical connections. This step includes precise drilling to ensure accurate via placement and dimensions, which is crucial for maintaining signal integrity.

- Electroplating: The vias and exposed copper surfaces are coated with a thin layer of metal through electroplating. This step is essential for creating conductive pathways and enhancing the overall electrical performance of the substrate.

- Etching: Excess copper and unwanted materials are removed through an etching process. This involves applying a chemical etchant to dissolve the unnecessary copper, leaving behind the desired circuit pattern and conductive pathways.

- Inspection and Testing: The fabricated substrates undergo rigorous inspection and testing to ensure they meet the required specifications. This includes checking for defects, verifying electrical performance, and assessing thermal properties.

- Cutting and Packaging: Finally, the substrates are cut to the desired size and shape according to customer specifications. They are then packaged for shipment, ensuring that they are protected during transport and handling.

These fabrication steps are designed to produce high-quality ISOLA I-TERA® MT40 substrates that meet the demanding requirements of RF and microwave applications, ensuring optimal performance and reliability.

The application of ceramic ISOLA I-TERA® MT40 (RF/MW) Substrate

Ceramic ISOLA I-TERA® MT40 (RF/MW) substrates are utilized in a variety of high-frequency applications due to their superior electrical and thermal properties. Here’s an overview of their applications:

- Mobile Communications: I-TERA® MT40 substrates are employed in mobile communication devices, including smartphones and tablets, to support high-speed data transmission and maintain signal integrity. Their low dielectric loss and controlled dielectric constant are crucial for reliable performance in RF circuits.

- Satellite Communications: In satellite systems, I-TERA® MT40 substrates are used for antenna systems, transponders, and other RF components. Their high thermal conductivity helps in managing the heat generated by high-power RF components, ensuring stable operation in space environments.

- Radar Systems: Radar systems, including those used in automotive and military applications, benefit from the high-frequency performance of I-TERA® MT40 substrates. The substrate’s low loss and stability under varying temperatures are essential for accurate and reliable radar signal processing.

- Microwave Circuits: I-TERA® MT40 is used in microwave circuits where precise impedance control and low signal loss are required. This includes applications such as microwave amplifiers, filters, and oscillators, where maintaining signal integrity is critical.

- High-Speed Digital Applications: The substrate is also suitable for high-speed digital applications where signal integrity is essential. This includes high-performance computing, networking equipment, and other electronic devices that operate at high frequencies.

- Medical Imaging: In medical imaging systems, such as MRI and ultrasound devices, the high-frequency capabilities of I-TERA® MT40 substrates contribute to the accuracy and clarity of imaging signals, enhancing diagnostic capabilities.

- Aerospace Applications:I-TERA® MT40 substrates are used in aerospace applications, where their high thermal conductivity and stability under extreme conditions are valuable for ensuring the performance and reliability of electronic systems.

Overall, the ceramic ISOLA I-TERA® MT40 (RF/MW) substrates are versatile and high-performing, making them suitable for a range of demanding applications in RF and microwave technologies.

FAQs about ISOLA I-TERA® MT40 (RF/MW) Substrate

What are the main advantages of I-TERA® MT40?

Key advantages include low dielectric loss tangent, high thermal conductivity, controlled dielectric constant, low coefficient of thermal expansion, and enhanced signal integrity.

What applications are suitable for I-TERA® MT40 substrates?

It is used in mobile communications, satellite communications, radar systems, microwave circuits, high-speed digital applications, medical imaging, and aerospace applications.

What is the fabrication process for I-TERA® MT40 substrates?

The fabrication process includes material preparation, lamination, curing, drilling, electroplating, etching, inspection, testing, and cutting.

How does I-TERA® MT40 perform in high-frequency applications?

I-TERA® MT40 performs excellently in high-frequency applications due to its low dielectric loss, high thermal conductivity, and stable electrical properties.

Can I-TERA® MT40 be used for high-power RF components?

Yes, its high thermal conductivity allows effective heat dissipation, making it suitable for high-power RF components.

What are the thermal management benefits of using I-TERA® MT40?

The substrate’s high thermal conductivity helps dissipate heat efficiently, which enhances the reliability and performance of electronic devices.

Your Website Name

Your Website Name