ISOLA FR406 Substrate Manufacturer

ISOLA FR406 Substrate Manufacturer,ISOLA FR406 is a high-performance substrate material designed for a wide range of PCB applications. It features excellent electrical properties with a low dielectric constant and low dissipation factor, which ensure superior signal integrity and minimal signal loss. The substrate provides outstanding thermal stability and mechanical strength, making it suitable for complex and high-layer-count circuit boards. FR406 is also known for its resistance to thermal cycling and high temperatures, enhancing reliability in demanding environments. Ideal for use in telecommunications, automotive, and high-speed digital systems, ISOLA FR406 combines robust performance with durability, making it a reliable choice for advanced electronic applications.

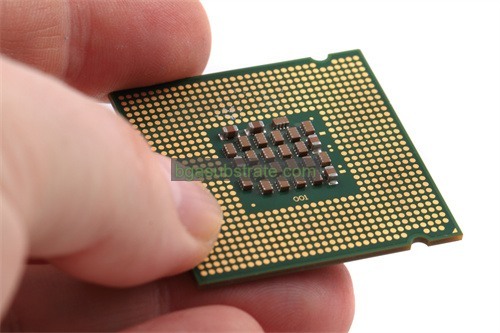

What is ISOLA FR406 Substrate?

ISOLA FR406 is a high-performance printed circuit board (PCB) substrate designed for use in demanding electronic applications. It belongs to the FR-4 family of materials but is distinguished by its enhanced performance characteristics. FR406 is formulated to meet the needs of high-frequency and high-speed applications, making it suitable for use in telecommunications, automotive, and aerospace industries.

The FR406 substrate is known for its excellent electrical and mechanical properties. It features a low dielectric constant (Dk) and low dissipation factor (Df), which help reduce signal loss and improve signal integrity. These properties make it ideal for high-speed digital and RF (radio frequency) applications where signal integrity is crucial. Additionally, FR406 has good thermal stability and can withstand high temperatures, which is essential for reliable performance in harsh operating conditions.

One of the key advantages of ISOLA FR406 is its compatibility with standard FR-4 processing techniques, which allows for easier integration into existing manufacturing processes. It provides a balance between performance and cost, offering high performance without the expense of more specialized materials.

In summary, ISOLA FR406 is a versatile and reliable substrate material that provides high electrical performance, thermal stability, and ease of processing, making it an excellent choice for advanced electronic applications requiring high-speed and high-frequency capabilities.

ISOLA FR406 Substrate Manufacturer

What is the ISOLA FR406 Substrate Design Guidelines?

The ISOLA FR406 substrate is a high-performance material used in PCB design, particularly suited for applications requiring superior electrical performance and thermal management. Here are some general design guidelines for using ISOLA FR406:

- Material Properties: FR406 is known for its excellent electrical properties and thermal stability. It offers a low dissipation factor, high dielectric strength, and good mechanical properties. Ensure that your design takes full advantage of these properties to achieve optimal performance.

- Layer Stack-up: For multilayer designs, carefully plan the layer stack-up to manage signal integrity and thermal dissipation. FR406’s thermal properties can help in managing heat, but proper layer design is crucial for signal integrity and mechanical stability.

- Copper Thickness: Choose the appropriate copper thickness based on current carrying requirements and impedance control. FR406 supports various copper weights, but ensure that the copper thickness aligns with your design requirements.

- Impedance Control: For high-speed designs, controlling impedance is crucial. Use controlled impedance traces to maintain signal integrity. The FR406 substrate allows for fine impedance control due to its stable dielectric properties.

- Thermal Management: Utilize FR406’s thermal properties to manage heat dissipation effectively. Ensure that thermal vias and heat sinks are designed appropriately to dissipate heat away from critical components.

- Drill and Routing Considerations: Follow recommended guidelines for drill sizes and routing to avoid delamination or other mechanical issues. The FR406 material generally has good drill performance, but adherence to recommended practices is essential.

- Design for Manufacturability: Consider manufacturability aspects, such as minimum trace width and spacing, to ensure that the design can be produced reliably and economically. FR406 is compatible with standard PCB fabrication processes, but specific design rules should be followed.

- Environmental Considerations: Ensure that the design adheres to environmental standards, such as RoHS compliance if required. FR406 is compatible with standard soldering processes and environmental requirements.

- Testing and Validation: Conduct thorough testing to validate the design’s performance. FR406’s consistent properties can help achieve reliable and repeatable results, but testing is crucial for confirming that the design meets all specifications.

These guidelines are intended to help maximize the performance and reliability of PCBs using ISOLA FR406. Always refer to the manufacturer’s datasheet and design guidelines for detailed specifications and recommendations.

The advantages of ISOLA FR406 Substrate

Here are the advantages of the ISOLA FR406 substrate:

- High Electrical Performance: FR406 provides excellent electrical properties, including a low dissipation factor, which minimizes signal loss and enhances signal integrity in high-speed applications.

- Thermal Stability: The substrate offers superior thermal stability and high thermal conductivity, which helps in effective heat dissipation and management, reducing the risk of thermal damage to components.

- Good Mechanical Strength: FR406 is known for its robust mechanical properties, providing good dimensional stability and durability, which enhances the overall reliability of the PCB.

- 4. Impedance Control: The material allows for precise impedance control, which is crucial for high-speed signal applications to ensure consistent and reliable signal transmission.

- Compatibility: FR406 is compatible with standard PCB fabrication processes, including etching, drilling, and plating, making it a versatile choice for a wide range of applications.

- Low Moisture Absorption: The substrate has low moisture absorption, which helps maintain its electrical properties and prevents degradation in high-humidity environments.

- High Dielectric Strength: The material provides high dielectric strength, ensuring effective isolation between conductive layers and reducing the risk of electrical breakdown.

- Thermal Cycling Resistance: FR406 exhibits good resistance to thermal cycling, maintaining its properties and performance through multiple temperature fluctuations.

- Cost-Effective: Compared to other high-performance substrates, FR406 offers a good balance of performance and cost, making it a cost-effective solution for high-performance PCB applications.

These advantages make ISOLA FR406 a popular choice for applications requiring high electrical performance, thermal management, and mechanical reliability.

What is the ISOLA FR406 Substrate Fabrication Process?

The fabrication process for ISOLA FR406 substrates generally follows the standard PCB manufacturing steps with some specific considerations for the FR406 material. Here’s an overview of the typical process:

- Material Preparation: Start with the FR406 laminate, which is available in various thicknesses and copper foil options. Ensure the material is stored and handled properly to maintain its properties.

- Layer Stacking: Stack the FR406 layers according to the PCB design. The stack-up must be precisely aligned to ensure proper bonding and performance. Each layer is typically separated by a prepreg (pre-impregnated resin) that acts as an adhesive during lamination.

- Lamination: Heat and pressure are applied to the stacked layers to bond them together. This process involves placing the stack in a lamination press where it is subjected to high temperatures (around 180-200°C) and pressures to cure the resin and create a solid, unified board.

- Drilling: After lamination, the PCB undergoes drilling to create vias and holes for component mounting and interlayer connections. FR406 handles drilling well, but appropriate drill speeds and feeds are used to avoid delamination.

- Plating: The drilled holes are plated with copper to establish electrical connections between layers. This involves electroless plating followed by electroplating to build up a sufficient layer of copper.

- Etching: Excess copper is removed from the surface of the board to define the circuit patterns. The PCB is exposed to an etching solution that removes the unwanted copper, leaving behind the desired circuit traces.

- Impedance Control: For high-speed designs, controlled impedance traces are implemented. FR406’s dielectric properties facilitate precise impedance control during the etching and layout stages.

- Solder Mask Application:A solder mask is applied to the PCB to protect the copper traces and prevent solder from bridging between pads. This mask is typically a green epoxy-based coating but can come in other colors.

- Silkscreen Printing: The silkscreen layer is printed on top of the solder mask to provide component labels and other important markings. This layer helps in the assembly and identification of components.

- Final Inspection and Testing: The fabricated PCB undergoes thorough inspection and testing to ensure it meets all design specifications. This includes electrical testing, visual inspection, and sometimes mechanical testing.

- Cutting and Routing: The final PCB is cut to the desired size and shape. Routing might be done to create specific cutouts or features as required by the design.

- Finish: The board is finished with a protective coating or surface finish, such as HASL (Hot Air Solder Leveling) or ENIG (Electroless Nickel/Immersion Gold), to protect the copper traces and ensure good solderability.

These steps outline the general process for fabricating ISOLA FR406 substrates, emphasizing the care needed to maintain the material’s performance characteristics throughout the manufacturing process.

The application of ceramic ISOLA FR406 Substrate

The ISOLA FR406 substrate is typically a type of high-performance PCB material, not a ceramic substrate. However, it is often compared to or used alongside ceramic materials in advanced electronic applications due to its superior electrical and thermal properties. Here’s an overview of the applications of ISOLA FR406 substrates and how they might relate to ceramic substrates:

- High-Speed Digital Circuits: ISOLA FR406’s low dissipation factor and high dielectric constant make it ideal for high-speed digital applications, where signal integrity is crucial. Its electrical performance can be compared to ceramic materials, which are also used in high-speed circuits.

- Telecommunications Equipment: The substrate’s excellent electrical properties and thermal stability make it suitable for telecommunications equipment, including base stations and networking hardware, where reliable signal transmission and heat management are essential.

- Aerospace and Defense: FR406’s robustness and thermal stability make it suitable for aerospace and defense applications, where the substrate must perform reliably under extreme conditions. Ceramic substrates are also used in these fields for similar reasons.

- Automotive Electronics: The high thermal stability and electrical performance of FR406 make it suitable for automotive electronics, where it can withstand the harsh operating environments and maintain signal integrity.

- Consumer Electronics: FR406 is used in various consumer electronics, such as smartphones and tablets, where its performance contributes to the overall reliability and efficiency of the devices.

- Power Electronics: The substrate’s good thermal management properties are beneficial for power electronics, where managing heat dissipation is crucial for the reliability and longevity of the components.

- Medical Devices: In medical electronics, where reliability and performance are critical, FR406 can be used in devices such as diagnostic equipment and imaging systems, providing stable performance in demanding environments.

- Test and Measurement Equipment: FR406’s precise impedance control and electrical performance make it suitable for test and measurement equipment, where accuracy and reliability are key.

In summary, while ISOLA FR406 is not a ceramic substrate, it shares some applications with ceramics, particularly where high performance, thermal stability, and reliability are required. The choice between FR406 and ceramic substrates depends on specific application needs, including electrical performance, thermal management, and cost considerations.

FAQs about ISOLA FR406 Substrate

What are the main advantages of ISOLA FR406?

Key advantages include low dissipation factor, high dielectric strength, good thermal stability, and compatibility with standard PCB fabrication processes. It also offers precise impedance control and low moisture absorption.

What types of applications are suitable for FR406?

FR406 is ideal for high-speed digital circuits, telecommunications equipment, aerospace and defense applications, automotive electronics, consumer electronics, power electronics, and medical devices.

How does FR406 compare to other substrates like ceramics?

While FR406 offers excellent performance for many applications, ceramic substrates generally provide superior thermal conductivity and mechanical rigidity. FR406 is often chosen for its cost-effectiveness and ease of fabrication compared to ceramics.

What are the fabrication processes for FR406?

The fabrication process includes material preparation, layer stacking, lamination, drilling, plating, etching, solder mask application, silkscreen printing, inspection, cutting, and finishing.

Can FR406 be used for high-speed signal applications?

Yes, FR406 is well-suited for high-speed signal applications due to its low dissipation factor and precise impedance control.

What are the thermal properties of FR406?

FR406 offers good thermal stability and thermal conductivity, helping to manage heat dissipation effectively in electronic devices.

Your Website Name

Your Website Name