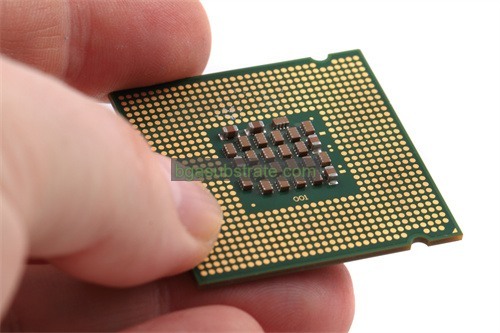

ISOLA 185HR Substrate Manufacturer

ISOLA 185HR Substrate Manufacturer,ISOLA 185HR is a high-performance substrate material designed for demanding PCB applications. It features excellent electrical properties, including a low dielectric constant and low dissipation factor, ensuring high signal integrity and minimal signal loss. The substrate offers outstanding thermal stability and mechanical strength, making it ideal for complex and high-layer-count circuit boards. ISOLA 185HR is also known for its superior resistance to high temperatures and thermal cycling, which enhances its reliability in harsh environments. Suitable for use in telecommunications, automotive, and high-speed digital systems, ISOLA 185HR combines robust performance with long-term durability for advanced electronic designs.

What is ISOLA 185HR Substrate?

ISOLA 185HR Substrate is a type of high-performance, high-frequency laminate material used in the manufacturing of printed circuit boards (PCBs). It is specifically designed for applications that demand excellent electrical performance and stability at high frequencies.

The “185HR” in the name refers to the specific formulation of the substrate, which includes a blend of materials tailored to provide superior dielectric properties. These properties are crucial in minimizing signal loss and maintaining signal integrity, especially in high-speed and high-frequency electronic applications.

Key features of ISOLA 185HR include its low dielectric loss tangent and stable dielectric constant, which contribute to reduced signal attenuation and improved signal integrity. The material is also known for its thermal stability and resistance to environmental factors, which helps ensure reliable performance in demanding conditions.

This substrate is commonly used in various high-tech fields, including telecommunications, aerospace, and automotive electronics, where precision and performance are critical. Its ability to support high-density interconnections and maintain signal quality makes it a valuable choice for advanced electronic systems and high-frequency circuits.

Overall, ISOLA 185HR Substrate represents a sophisticated solution for modern PCB manufacturing, offering a balance of performance, reliability, and durability in high-frequency electronic applications.

ISOLA 185HR Substrate Manufacturer

What is the ISOLA 185HR Substrate Design Guidelines?

Design guidelines for ISOLA 185HR Substrate are essential for ensuring optimal performance and reliability in high-frequency printed circuit board (PCB) applications. Here are some key considerations:

- Signal Integrity: Maintain controlled impedance throughout the PCB design. Use impedance-matching techniques to minimize signal reflections and losses. Properly route high-speed signal traces and use differential pairs where applicable to preserve signal integrity.

- Layer Stackup: Design the layer stackup to minimize signal loss and cross-talk. Ensure that the dielectric thickness between signal layers is appropriate for the operating frequency. Maintain consistent dielectric thicknesses to ensure uniform signal propagation.

- Thermal Management: Implement effective thermal management strategies. ISOLA 185HR has good thermal stability, but managing heat dissipation is still crucial for maintaining substrate performance and longevity. Use thermal vias and heat sinks as needed.

- Via Design: Optimize via designs to reduce inductance and signal degradation. Use appropriate via sizes and spacing to avoid introducing impedance mismatches. Consider blind and buried vias to minimize signal path disruptions.

- Material Handling: Follow proper handling procedures to avoid damage. ISOLA 185HR is designed for high performance, but physical damage during fabrication or assembly can impact its properties. Handle materials with care and avoid exposure to extreme conditions.

- Testing and Validation: Conduct thorough testing of the PCB design to ensure that it meets the required performance specifications. Perform signal integrity analysis and thermal testing to validate that the design performs as expected under operational conditions.

- Design Tools: Utilize advanced design tools and simulation software to model the high-frequency behavior of the PCB. Accurate simulation helps in predicting performance and identifying potential issues early in the design process.

By adhering to these guidelines, designers can leverage the full capabilities of ISOLA 185HR Substrate, ensuring high performance, reliability, and efficiency in their high-frequency PCB applications.

The advantages of ISOLA 185HR Substrate

The ISOLA 185HR Substrate offers several advantages, particularly in high-frequency and high-performance applications. Here are the key benefits:

- Excellent Electrical Performance: ISOLA 185HR provides low dielectric loss tangent and stable dielectric constant, which are crucial for minimizing signal attenuation and maintaining signal integrity in high-speed and high-frequency circuits. This results in improved performance and reliability of electronic systems.

- High Thermal Stability: The substrate exhibits strong thermal stability, ensuring reliable performance even in demanding conditions. It can handle high temperatures without significant degradation of its electrical properties, making it suitable for applications with varying thermal environments.

- Low Signal Loss: Due to its low dielectric loss, ISOLA 185HR minimizes signal loss and distortion. This is particularly important in high-frequency applications where maintaining signal quality is critical.

- Reduced Crosstalk:The material’s properties help in reducing electromagnetic interference and crosstalk between traces, enhancing the overall performance and reliability of the PCB.

- Enhanced Mechanical Strength: ISOLA 185HR offers good mechanical properties, contributing to the structural integrity of the PCB. This makes it suitable for applications that require robust and durable substrates.

- Versatility: The substrate is adaptable to various high-tech applications, including telecommunications, aerospace, and automotive electronics. Its versatility allows it to meet the specific requirements of different high-frequency and high-performance designs.

- Consistent Performance: The material’s consistent dielectric properties ensure uniform performance across the PCB, which is essential for high-precision applications where deviations can impact functionality.

Overall, ISOLA 185HR Substrate is valued for its superior electrical and thermal characteristics, mechanical strength, and versatility, making it a preferred choice for advanced electronic applications demanding high performance and reliability.

What is the ISOLA 185HR Substrate Fabrication Process?

The fabrication process for ISOLA 185HR Substrate involves several key steps to ensure high-quality performance and reliability in high-frequency printed circuit boards (PCBs). Here’s an overview of the typical process:

- Material Preparation: The raw ISOLA 185HR laminate material is prepared and inspected for quality. This involves ensuring that the laminate sheets meet the required specifications for dielectric properties, thickness, and other physical attributes.

- Lamination: The laminate sheets are layered and bonded together under heat and pressure to form the core of the PCB. This process involves applying adhesive layers and using a lamination press to consolidate the layers into a single, cohesive substrate.

- Drilling: Once the laminate is laminated and cured, precise drilling is performed to create holes for vias and component mounting. Advanced drilling techniques and machinery are used to ensure accuracy and minimize damage to the substrate.

- Etching: After drilling, a layer of copper is deposited on the substrate. The copper layer is then etched away to create the desired circuit patterns and traces. This step involves applying a photoresist layer, exposing it to UV light through a mask, and then etching away the unprotected copper.

- Plating: Vias and holes are plated with copper to ensure electrical connectivity. This step involves electroplating, where a thin layer of copper is deposited on the interior walls of the holes and vias to provide a conductive path.

- Surface Finishing: The surface of the PCB is treated with a finish to protect the copper traces and improve solderability. Common finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel/Immersion Gold), or other surface treatments suitable for high-frequency applications.

- Inspection and Testing: The fabricated substrate undergoes rigorous inspection and testing to ensure it meets performance specifications. This includes visual inspections, electrical testing, and high-frequency signal testing to validate the integrity of the circuit patterns and overall substrate quality.

- Cutting and Routing: The final substrate is cut to the required dimensions and shapes. Precision routing ensures that the substrate fits the specific design requirements and integrates seamlessly into the final electronic assembly.

By following these steps, the ISOLA 185HR Substrate is manufactured to meet the high-performance standards required for advanced electronic applications, providing reliability and excellent electrical characteristics for high-frequency PCB designs.

The application of ceramic ISOLA 185HR Substrate

The ISOLA 185HR Substrate is predominantly known for its applications in high-frequency and high-performance printed circuit boards (PCBs), but ceramic variants of substrates can also play crucial roles in various advanced technologies. Here’s how ceramic versions of substrates like ISOLA 185HR are applied:

- Telecommunications: Ceramic substrates such as ISOLA 185HR are used in high-frequency components like RF (radio frequency) modules, antennas, and communication devices. Their low dielectric loss and stable dielectric constant make them ideal for minimizing signal attenuation and maintaining signal integrity in telecommunication systems.

- Aerospace:In aerospace applications, where reliability and performance are critical, ceramic substrates are used in avionics, satellite communication systems, and radar systems. The high thermal stability and mechanical strength of ceramic substrates help them withstand harsh environments and temperature variations.

- Automotive Electronics: High-performance automotive electronics, including advanced driver-assistance systems (ADAS) and infotainment systems, benefit from the use of ceramic substrates. The material’s ability to handle high-frequency signals and its thermal stability are crucial for ensuring the reliability of automotive electronics under varying operating conditions.

- Medical Devices: In medical electronics, ceramic substrates are used in diagnostic equipment, imaging systems, and implantable devices. Their high-frequency performance and biocompatibility (in some cases) make them suitable for precision medical applications where performance and safety are paramount.

- Power Electronics: Ceramic substrates are also applied in power electronics, including power amplifiers and converters. Their excellent thermal conductivity helps in efficient heat dissipation, which is essential for maintaining the performance and longevity of power electronic components.

- Consumer Electronics:High-performance consumer electronics such as high-speed data processors and advanced audio equipment use ceramic substrates to ensure signal integrity and reliability. The material’s properties contribute to better performance in high-frequency applications and complex electronic systems.

In summary, ceramic versions of ISOLA 185HR Substrate are utilized across a range of advanced and high-performance applications, providing excellent electrical, thermal, and mechanical properties that enhance the functionality and reliability of electronic systems in telecommunications, aerospace, automotive, medical, and consumer electronics.

FAQs about ISOLA 185HR Substrate

What is ISOLA 185HR Substrate?

ISOLA 185HR Substrate is a high-performance laminate material designed for high-frequency printed circuit boards (PCBs). It offers excellent electrical characteristics, including low dielectric loss and stable dielectric constant, making it suitable for applications requiring high signal integrity and performance.

What are the key features of ISOLA 185HR?

Key features of ISOLA 185HR include low dielectric loss tangent, stable dielectric constant, high thermal stability, reduced signal loss, and mechanical strength. These properties make it ideal for high-frequency and high-speed applications.

What applications are suitable for ISOLA 185HR Substrate?

ISOLA 185HR is suitable for a wide range of high-performance applications, including telecommunications, aerospace, automotive electronics, medical devices, power electronics, and consumer electronics. It is used in components that require precise signal integrity and reliability.

How does ISOLA 185HR compare to other substrates?

Compared to other substrates, ISOLA 185HR offers superior performance in high-frequency applications due to its low dielectric loss and stable dielectric constant. It often outperforms standard FR4 substrates in applications requiring high-speed data transmission and low signal attenuation.

What is the fabrication process for ISOLA 185HR?

The fabrication process for ISOLA 185HR involves material preparation, lamination, drilling, etching, plating, surface finishing, inspection, and cutting. Each step is designed to ensure high-quality performance and reliability in the final PCB.

What are the design considerations when using ISOLA 185HR?

Design considerations include maintaining controlled impedance, optimizing layer stackup, effective thermal management, proper via design, and thorough testing. These practices help maximize the performance and reliability of the PCB using ISOLA 185HR.

Your Website Name

Your Website Name