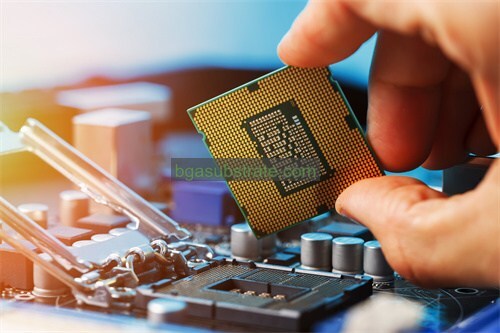

メグトロン 2 基板 生産者

メグトロン 2 基板メーカー,メグトロン 2 Substrate is a high-performance material designed for demanding high-speed digital and RF applications. It features a low dielectric constant and low dissipation factor, ensuring minimal signal loss and excellent signal integrity at high frequencies. メグトロン 2 offers superior thermal stability and reliability, crucial for applications in telecommunications, コンピューティング, および航空宇宙産業. Its robust mechanical properties, including low thermal expansion and high glass transition temperature, support reliable operation under varying environmental conditions. Engineers rely on Megtron 2 Substrate for its ability to facilitate complex circuit designs and maintain consistent electrical performance, making it an ideal choice for advanced electronic systems requiring high-speed data transmission and reliability.

メグトロンとは 2 基板?

メグトロン 2 substrate is a type of high-performance PCB material developed by Panasonic. It belongs to the Megtron series, known for its excellent electrical properties and reliability in high-frequency applications. メグトロン 2 offers low transmission loss characteristics, making it suitable for high-speed digital and RF/microwave circuits where signal integrity is crucial. This substrate material also provides good thermal stability and mechanical strength, which are essential for demanding environmental conditions and reliability requirements in modern electronics. Designers often choose Megtron 2 for applications requiring high data rates, such as telecommunications equipment, 自動車用電子機器, and aerospace systems, where maintaining signal integrity and reducing electromagnetic interference (EMIの) are critical factors. Its properties contribute to enhancing overall performance and reliability in complex electronic designs.

メグトロン 2 基板メーカー

メグトロンとは 2 基板設計ガイドライン?

の設計ガイドライン メグトロン 2 基板 primarily focus on maximizing its performance capabilities, ensuring signal integrity, and maintaining reliability. ここでは、設計ガイドラインで一般的に取り上げられる主な側面をいくつか紹介します:

- 材料特性: Understanding the specific electrical and mechanical properties of Megtron 2, その誘電率など (DKの), dissipation factor (Dfの), 熱伝導率, and coefficient of thermal expansion (CTEの).

- シグナルインテグリティ: Ensuring controlled impedance matching to minimize signal loss and reflection, which is critical for high-speed digital and RF/microwave applications.

- Routing and Layout: Guidelines on trace widths, スペーシング, and via design to maintain signal integrity and reduce crosstalk and EMI.

- サーマルマネジメント: Recommendations for thermal vias, copper pours, and heatsinks to manage heat dissipation effectively, 特にハイパワーアプリケーションの場合.

- 機械的な考慮事項: Designing for mechanical stability and reliability, considering factors such as board thickness, stack-up design, and mounting requirements.

- 製造可能性: Guidelines for fabrication processes specific to Megtron 2, including handling, 錬成, 鍍金, and soldering techniques to ensure reliability and yield during manufacturing.

- Environmental Factors: Considerations for environmental conditions, such as humidity, temperature extremes, and vibration, to ensure long-term reliability in various operating environments.

- コンプライアンスと基準: Adherence to industry standards and compliance with relevant regulations for electronic products.

These guidelines are crucial for engineers and designers to leverage the full potential of Megtron 2 substrate in their electronic designs, optimizing performance while ensuring reliability and manufacturability.

Megtronの利点 2 基板

メグトロン 2 基板 offers several advantages that make it a preferred choice in high-performance electronic applications:

- Low Transmission Loss: メグトロン 2 has low dielectric loss (Dfの), which results in minimal signal attenuation and excellent signal integrity. This property is crucial for high-speed digital and RF/microwave circuits where maintaining signal quality is paramount.

- 高い熱伝導率: It has superior thermal conductivity compared to standard FR-4 materials, enabling efficient heat dissipation. This is beneficial in applications requiring high power or operating in elevated temperature environments.

- 優れた電気的特性: With a high dielectric constant (DKの), メグトロン 2 supports impedance control and high-frequency performance, making it suitable for advanced electronic designs that demand precise signal propagation.

- Mechanical Strength and Reliability: It offers good mechanical stability, 耐久性, and resistance to mechanical stress, which ensures reliability in complex electronic assemblies.

- 環境耐久性: メグトロン 2 is designed to withstand harsh environmental conditions, including moisture, 湿度, and temperature fluctuations, enhancing the longevity and reliability of electronic devices.

- Compatibility and Versatility: 標準のPCB製造プロセスと互換性があります, allowing for ease of manufacturing and assembly. Its versatility makes it suitable for a wide range of applications in telecommunications, 自動車, 航宇, and other industries.

- 電磁干渉の低減 (EMIの): The material’s properties help in reducing EMI, improving overall electromagnetic compatibility (EMC) in electronic systems.

全, メグトロン 2 substrate’s combination of electrical performance, 熱管理機能, 機械的な堅牢性, and environmental durability makes it a preferred choice for high-end electronic designs where reliability and performance are critical considerations.

メグトロンとは 2 基板製造プロセス?

Megtronの製造プロセス 2 substrate involves several key steps to ensure the material’s properties are utilized effectively and the final PCB meets high-performance standards. Here are the typical steps involved in fabricating a PCB using Megtron 2 基板:

- 材料の準備: メグトロン 2 material sheets are prepared according to the required thickness and dimensions for the PCB.

- 錬成: Holes for vias and component leads are drilled into the Megtron 2 sheets using precision drilling equipment. Care is taken to maintain accuracy and minimize mechanical stress on the material.

- レイヤースタッキング (積層):メグトロン 2 sheets are stacked together with prepreg layers and copper foils according to the PCB design’s layer stack-up. The stack is then pressed together under high temperature and pressure to form a solid laminate.

- Circuit Patterning (Lithography):The PCB circuit pattern is transferred onto the Megtron 2 laminate using a photoresist process. This involves applying a photoresist material, exposing it to UV light through a photomask of the circuit pattern, and developing it to create the copper circuitry.

- エッチング:Exposed copper areas not protected by the developed photoresist are etched away using chemical processes, leaving behind the desired circuit traces and pads.

- 表面仕上げ:The exposed copper surfaces are often treated with surface finishes like HASL (熱風はんだレベリング), エニグ (無電解ニッケル浸漬金), または OSP (Organic Solderability Preservatives) to improve solderability and protect against oxidation.

- ソルダーマスクアプリケーション:A solder mask layer is applied over the circuitry to insulate and protect the copper traces, except where soldering is required.

- Silkscreen Printing:Component designators, logos, and other identifying marks are printed onto the PCB surface using silkscreen ink.

- 最終検査と試験:The completed Megtron 2 PCB undergoes rigorous inspection and testing to verify dimensional accuracy, 電気的導通, and overall quality. This may include electrical testing, solderability testing, および目視検査.

- Assembly:テストと承認が完了したら, the Megtron 2 PCB is ready for component assembly, where electronic components are mounted onto the board using soldering processes such as reflow soldering or wave soldering.

Megtronの製造プロセス 2 substrates requires careful adherence to design guidelines and quality control measures to ensure that the final PCB meets the high-performance requirements demanded by advanced electronic applications.

セラミックメグトロンの応用 2 基板

メグトロン 2 基板, despite its name suggesting a ceramic material, is actually a high-performance epoxy-based laminate. It is often confused with ceramic substrates due to its excellent electrical properties and thermal management capabilities, which are critical for various high-frequency and high-speed electronic applications. Here are some typical applications of Megtron 2 基板:

- High-Speed Digital Devices: メグトロン 2 is used in high-speed digital circuits where signal integrity is crucial. Its low dielectric loss (Dfの) and high thermal conductivity help minimize signal attenuation and manage heat dissipation effectively, supporting the performance of devices like routers, servers, and high-speed data communication equipment.

- RF/Microwave Applications: Due to its high dielectric constant (DKの) および低損失正接, メグトロン 2 is suitable for RF/microwave circuits. It enables precise impedance control, low insertion loss, and minimal cross-talk, making it ideal for applications in radar systems, 無線通信機器, および衛星通信システム.

- カーエレクトロニクス: Megtron 2’s robust mechanical properties and reliability in harsh environments make it suitable for automotive electronics. It is used in advanced driver assistance systems (ADASの), エンジンコントロールユニット (ECU(エキュエート), and infotainment systems where high reliability and thermal stability are essential.

- 航空宇宙・防衛: 航空宇宙および防衛用途, メグトロン 2 is chosen for its ability to withstand extreme temperatures, 振動, and moisture. It is used in avionics, レーダーシステム, military communication equipment, and satellite payloads where durability and performance under demanding conditions are critical.

- 産業機器: メグトロン 2 finds application in industrial equipment such as power supplies, industrial control systems, and test and measurement instruments. Its high thermal conductivity helps in dissipating heat generated by power electronics, ensuring reliable operation in industrial environments.

- 医療用電子機器: For medical devices and equipment requiring high reliability and precision, メグトロン 2 is used in applications such as diagnostic imaging systems, 患者モニタリングデバイス, and medical instrumentation where signal accuracy and thermal management are crucial.

- 家電: 家電製品, メグトロン 2 can be found in high-performance computing devices, ゲーム機, and high-definition multimedia devices where high-speed data transfer and reliability are necessary for seamless operation.

全, メグトロン 2 substrate’s combination of electrical performance, 熱管理機能, 機械的強度, and reliability makes it a versatile choice for a wide range of advanced electronic applications across various industries.

Megtronについてよくある質問 2 基板

メグトロンとは 2 基板?

メグトロン 2 is a high-performance epoxy-based laminate used as a PCB material. It offers excellent electrical properties, 低誘電損失 (Dfの), 高い熱伝導率, と機械的強度, making it suitable for high-frequency and high-speed electronic applications.

What are the advantages of using Megtron 2 基板?

メグトロン 2 substrate provides advantages such as low transmission loss, 効果的な熱放散のための高い熱伝導率, excellent signal integrity, 機械的安定性, 過酷な環境での信頼性. It also reduces electromagnetic interference (EMIの) and supports precise impedance control.

Where is Megtron 2 substrate commonly used?

It is commonly used in applications requiring high-speed digital circuits, RF/マイクロ波回路, 自動車用電子機器, 航空宇宙および防衛システム, industrial equipment, 医療用電子機器, および家庭用電化製品.

メグトロンはどうですか 2 substrate compare to traditional FR-4 materials?

Compared to FR-4, メグトロン 2 offers superior electrical performance, 熱管理機能, and reliability under demanding conditions. It is specifically designed for applications that require high-frequency performance and stringent reliability standards.

What are the key design considerations when using Megtron 2 基板?

Design considerations include impedance control, サーマルマネジメント, 機械的安定性, and compatibility with manufacturing processes. Attention to these factors ensures optimal performance and reliability of electronic circuits using Megtron 2.

Is Megtron 2 substrate compatible with standard PCB fabrication processes?

はい, メグトロン 2 substrate is compatible with standard PCB fabrication processes. It can be processed using techniques such as drilling, レイヤースタッキング (積層), circuit patterning (lithography), エッチング, 表面仕上げ, ソルダーマスクアプリケーション, and silkscreen printing.

What are the environmental considerations for using Megtron 2 基板?

メグトロン 2 substrate is designed to withstand harsh environmental conditions, including temperature variations, 湿度, と機械的ストレス. It is suitable for applications requiring long-term reliability in diverse operating environments.

あなたのウェブサイト名

あなたのウェブサイト名