Mitsubishi BT LED Substrate Fabricante

Fabricante de sustratos LED Mitsubishi BT,Mitsubishi BT LED Substrate is a specialized material designed for high-performance LED applications. It boasts excellent thermal conductivity, ensuring efficient heat dissipation and prolonged LED lifespan. With low thermal expansion and superior mechanical strength, Mitsubishi BT LED Substrate supports reliable operation in challenging environments. It enables precise LED chip placement and intricate circuit designs, enhancing overall light output and efficiency. This substrate is crucial in automotive lighting, display technology, and general illumination where reliability, Gestión térmica, and performance consistency are essential. Mitsubishi BT LED Substrate continues to set benchmarks in LED packaging, supporting advancements in energy-efficient lighting solutions.

What is Mitsubishi BT LED Substrate?

Mitsubishi BT LED Substrate, also known as Mitsubishi BT Substrate, is a specialized type of substrate designed for LED (Light Emitting Diode) Aplicaciones. It is crafted using advanced materials and manufacturing processes to meet the specific requirements of LED technology.

These substrates typically feature high thermal conductivity, Excelente estabilidad térmica, and precise dimensional control. These properties are crucial for LEDs because they ensure efficient heat dissipation, which is essential for maintaining LED performance and longevity.

Mitsubishi BT Substrates often utilize materials like ceramics or metal-matrix composites that offer superior thermal properties compared to traditional PCB materials. This helps in managing the heat generated during LED operation, preventing overheating that could degrade performance or shorten lifespan.

In addition to thermal management, Mitsubishi BT LED Substrates are engineered to provide reliable electrical connectivity and mechanical support for LED components. They may incorporate advanced features such as optimized surface finishes and mounting options tailored for LED chip attachment.

En general, Mitsubishi BT LED Substrates play a critical role in enhancing the efficiency, fiabilidad, and lifespan of LED devices, making them a preferred choice in various lighting and display applications where high performance and durability are paramount.

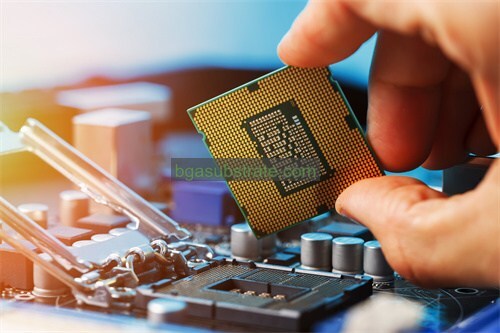

Fabricante de sustratos LED Mitsubishi BT

What is the Mitsubishi BT LED Substrate Design Guidelines?

Las directrices de diseño para Mitsubishi BT LED Substrates focus on optimizing their performance and reliability in LED applications. Here are key aspects typically covered in these guidelines:

- Material Selection: Emphasizes the use of high thermal conductivity materials such as ceramics or metal-matrix composites to ensure efficient heat dissipation from the LED chips.

- Gestión térmica: Provides recommendations for thermal vias, heat sinks, and layout designs to effectively dissipate heat generated by the LEDs, thereby enhancing overall system reliability and longevity.

- Estabilidad dimensional:Specifies tolerances and dimensional stability requirements to ensure precise alignment and mounting of LED components, which is crucial for maintaining optical performance.

- Electrical Performance: Guidelines on routing of electrical traces and vias to minimize parasitic resistance and optimize electrical connectivity between the LED chips and external circuitry.

- Mechanical Durability: Recommends substrate thickness, reinforcement techniques, and mounting options to withstand mechanical stresses during handling, assembly, and operation.

- Surface Finishes: Specifies compatible surface finishes that ensure reliable soldering and bonding of LED chips, connectors, and other components.

- Manufacturing Processes: Outlines preferred manufacturing processes such as laser drilling for vias, precision cutting for substrate shaping, and quality control measures to maintain consistency and reliability.

- Consideraciones medioambientales: Addresses factors like moisture resistance, chemical compatibility, and reliability under various environmental conditions to ensure long-term performance.

- Compliance and Standards: Ensures compliance with industry standards and regulations related to LED substrates, including RoHS compliance for environmental safety.

Siguiendo estas pautas, designers and manufacturers can optimize the performance, fiabilidad, and manufacturability of Mitsubishi BT LED Substrates, meeting the stringent requirements of modern LED applications across lighting, automotor, display, and other sectors.

The advantages of Mitsubishi BT LED Substrate

Mitsubishi BT LED Substrates offer several advantages that make them highly suitable for LED applications:

- Alta conductividad térmica: These substrates typically feature materials with excellent thermal conductivity properties, such as ceramics or metal-matrix composites. This helps in efficiently dissipating heat generated by the LEDs, ensuring optimal performance and extending the lifespan of the LED devices.

- Estabilidad térmica:They are designed to maintain stable thermal properties across a wide range of temperatures, ensuring consistent LED performance even under demanding operating conditions.

- Dimensional Precision: Mitsubishi BT LED Substrates are manufactured with precise dimensional control, ensuring accurate alignment and mounting of LED chips. This precision is crucial for maintaining optical performance and reliability.

- Mechanical Durability: They are engineered to withstand mechanical stresses during handling, assembly, and operation. This durability is enhanced through appropriate substrate thickness, reinforcement techniques, and mounting options.

- Electrical Performance: These substrates offer optimized electrical connectivity, with designs that minimize parasitic resistance and ensure reliable signal transmission between the LED components and external circuitry.

- Compatibility with LED Manufacturing Processes: Mitsubishi BT LED Substrates are compatible with various LED manufacturing processes, including soldering, bonding, and assembly techniques. This compatibility streamlines production processes and enhances yield rates.

- Environmental Stability: They are designed to withstand environmental factors such as moisture, chemicals, and temperature fluctuations, ensuring robust performance and longevity in diverse application environments.

- Customization and Flexibility: Manufacturers can customize Mitsubishi BT LED Substrates to meet specific design requirements, including size, shape, and material composition, offering flexibility for different LED applications.

En general, these advantages make Mitsubishi BT LED Substrates a preferred choice for high-performance LED lighting, displays, automotive lighting, and other applications where reliability, Gestión térmica, and electrical performance are critical considerations.

What is the Mitsubishi BT LED Substrate Fabrication Process?

The fabrication process of Mitsubishi BT LED Substrates involves several key steps to ensure the materials are prepared and shaped into substrates suitable for LED applications. Here’s a general overview of the typical fabrication process:

- Material Selection: Mitsubishi BT LED Substrates are often made from high thermal conductivity materials such as ceramics (like alumina or aluminum nitride) or metal-matrix composites. The choice of material depends on the specific thermal and electrical performance requirements of the LED application.

- Preparación del material: The selected raw materials undergo preparation processes such as mixing, forming, and drying to achieve the desired composition and consistency. This ensures uniformity and quality in the substrate material.

- Shaping and Cutting: The prepared material is then shaped into sheets or panels of the desired thickness using techniques such as pressing, casting, or extrusion. Precision cutting methods, including laser cutting or mechanical cutting, are employed to achieve the exact dimensions required for the substrate.

- Surface Preparation: The substrate surfaces are carefully prepared to ensure cleanliness and proper bonding with subsequent layers or components. This may involve treatments such as cleaning, chemical etching, or surface coating depending on the specific application requirements.

- Via Formation: Vias (Agujeros) are drilled or punched into the substrate material using high-precision techniques. These vias are essential for electrical interconnects between different layers of the substrate and for thermal management through the attachment of heat sinks or thermal vias.

- Metallization: Conductive metal layers (típicamente cobre) are deposited onto the substrate surfaces and inside the vias using techniques like sputtering, electroplating, or chemical vapor deposition (CVD). This metallization process forms the conductive pathways necessary for electrical connections and thermal dissipation.

- Laminación (if applicable): In some cases, multiple layers of substrates or additional functional layers (such as dielectric layers for impedance control) are laminated together under heat and pressure. This lamination process enhances substrate strength and electrical performance.

- Acabado superficial: The final substrate surface is finished to ensure compatibility with LED chip attachment processes such as soldering or epoxy bonding. This may involve applying solder mask, surface finishes (like immersion tin or gold), or protective coatings to enhance durability and reliability.

- Control de calidad: Throughout the fabrication process, rigorous quality control measures are implemented to monitor material properties, dimensional accuracy, and adherence to design specifications. Testing methods such as dimensional inspection, electrical testing, and thermal performance testing are conducted to ensure substrate reliability.

By following these fabrication steps, Mitsubishi BT LED Substrates are manufactured to meet the demanding requirements of LED applications, offering high thermal conductivity, precise dimensional control, and reliable electrical performance essential for efficient and durable LED devices.

The application of ceramic Mitsubishi BT LED Substrate

Mitsubishi BT LED Substrates, made from high thermal conductivity ceramics or metal-matrix composites, find application across various industries where LED performance, fiabilidad, y la gestión térmica son fundamentales. Estas son algunas de las aplicaciones clave:

- LED Lighting:Mitsubishi BT LED Substrates are extensively used in LED lighting applications, including residential, commercial, and industrial lighting fixtures. Their high thermal conductivity helps in efficiently dissipating heat generated by the LEDs, ensuring longer lifespan and sustained performance.

- Automotive Lighting: In automotive applications, Mitsubishi BT LED Substrates are employed in headlights, taillights, interior lighting, and other automotive lighting systems. They provide robust thermal management capabilities, essential for maintaining LED brightness and reliability under varying operating conditions.

- Display Technology: LED displays, such as large-scale outdoor displays, digital signage, and indoor displays in stadiums or commercial spaces, benefit from Mitsubishi BT LED Substrates. These substrates support high-density LED arrays while managing heat effectively, ensuring consistent display quality and longevity.

- Electrónica de consumo: They are used in consumer electronics products like televisions, monitors, and handheld devices where LED backlighting or display panels require efficient thermal dissipation to prevent overheating and ensure stable performance.

- Medical and Scientific Equipment:Mitsubishi BT LED Substrates are employed in medical devices, laboratory equipment, and scientific instruments that utilize LED technology for lighting or imaging purposes. Their thermal stability and reliability are crucial in these precision applications.

- Aplicaciones Industriales: LED-based industrial equipment and machinery, such as inspection systems, automated manufacturing equipment, and machine vision systems, utilize Mitsubishi BT LED Substrates to ensure reliable operation and longevity in demanding industrial environments.

- Aeroespacial y Defensa: En aplicaciones aeroespaciales y de defensa, where reliability under extreme conditions is paramount, Mitsubishi BT LED Substrates are used in aircraft lighting, military vehicle lighting, and portable lighting systems due to their robust thermal management capabilities.

- Specialized Lighting: Applications such as horticultural lighting (for plant growth), underwater lighting (for marine applications), and UV curing systems (for industrial processes) also benefit from Mitsubishi BT LED Substrates, where customized thermal solutions are required.

En cada una de estas aplicaciones, Mitsubishi BT LED Substrates play a crucial role in enhancing LED performance, extending product lifespan, and ensuring consistent operational efficiency through effective thermal management and reliable electrical connectivity.

FAQs about Mitsubishi BT LED Substrate

What is Mitsubishi BT LED Substrate?

Mitsubishi BT LED Substrate is a specialized substrate designed for LED applications, known for its high thermal conductivity and excellent thermal management properties. It helps dissipate heat generated by LEDs, ensuring reliable performance and longevity.

What are the advantages of Mitsubishi BT LED Substrate?

The advantages include high thermal conductivity, Estabilidad térmica, precise dimensional control, durability, and optimized electrical performance. These properties make it ideal for demanding LED applications where heat dissipation and reliability are critical.

What materials are Mitsubishi BT LED Substrates made of?

They are typically made from ceramics such as alumina or aluminum nitride, or metal-matrix composites. These materials offer superior thermal conductivity compared to traditional PCB materials, essential for efficient heat dissipation in LEDs.

Where are Mitsubishi BT LED Substrates used?

They are used in various industries and applications, including LED lighting (residential, commercial, automotor), displays (indoor and outdoor), Electrónica de consumo, medical equipment, industrial machinery, aeroespacial, y defensa.

How do Mitsubishi BT LED Substrates enhance LED performance?

By efficiently dissipating heat, Mitsubishi BT LED Substrates prevent overheating of LED chips, which can degrade performance and lifespan. This thermal management capability ensures consistent brightness, color quality, and reliability of LED devices.

What manufacturing processes are involved in producing Mitsubishi BT LED Substrates?

The fabrication process typically includes material preparation, shaping and cutting, via formation, metallization, surface preparation and finishing, laminación (if applicable), and rigorous quality control measures to ensure reliability and adherence to specifications.

Are Mitsubishi BT LED Substrates customizable?

Sí, manufacturers can customize Mitsubishi BT LED Substrates to meet specific design requirements, including dimensions, material composition, surface finishes, and electrical properties, to suit different LED applications.

What standards or certifications do Mitsubishi BT LED Substrates comply with?

They are often manufactured to comply with industry standards such as RoHS (Restriction of Hazardous Substances), ensuring environmental safety and compatibility with global regulatory requirements.

El nombre de su sitio web

El nombre de su sitio web